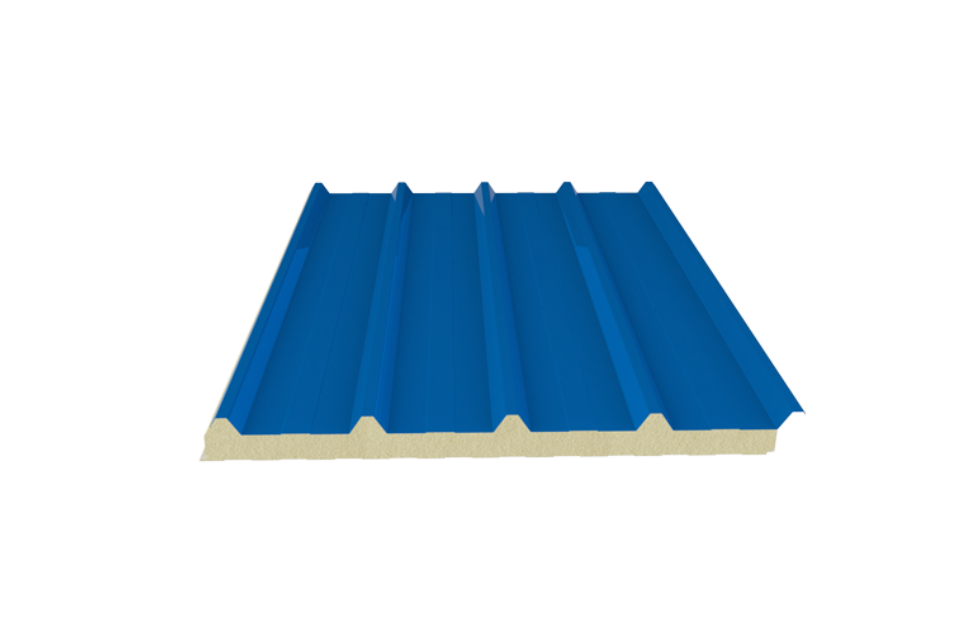

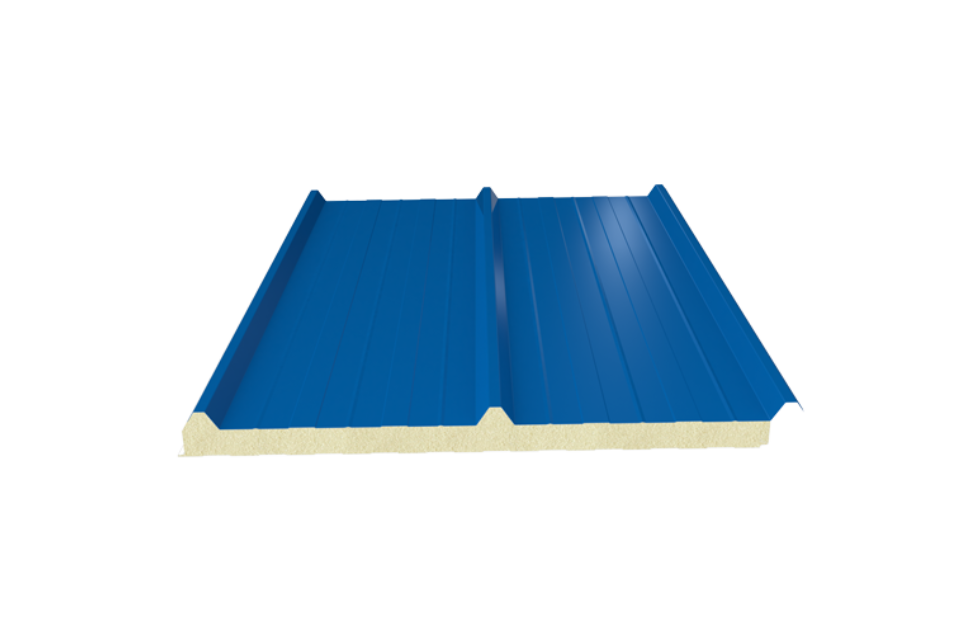

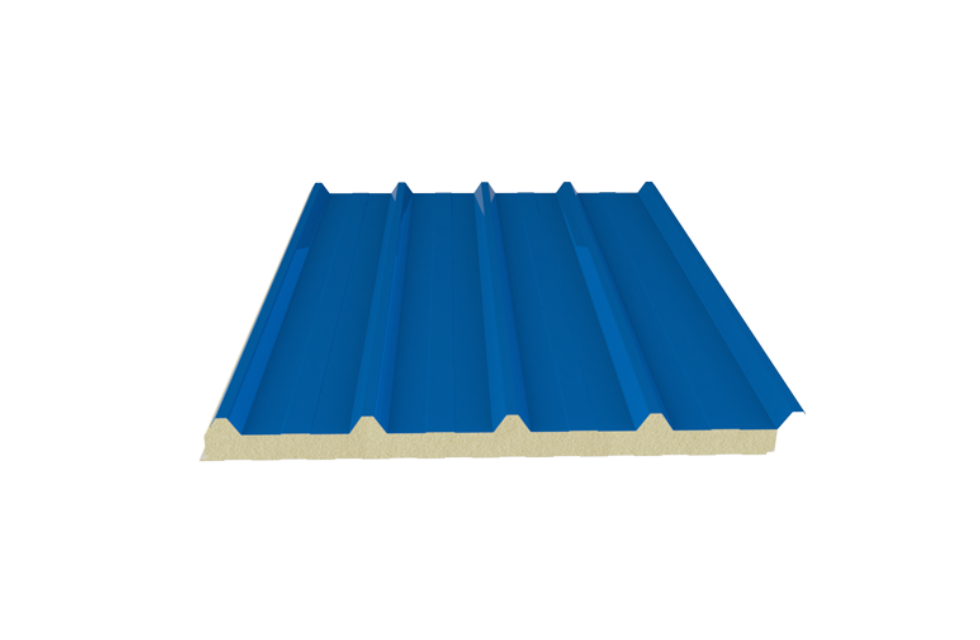

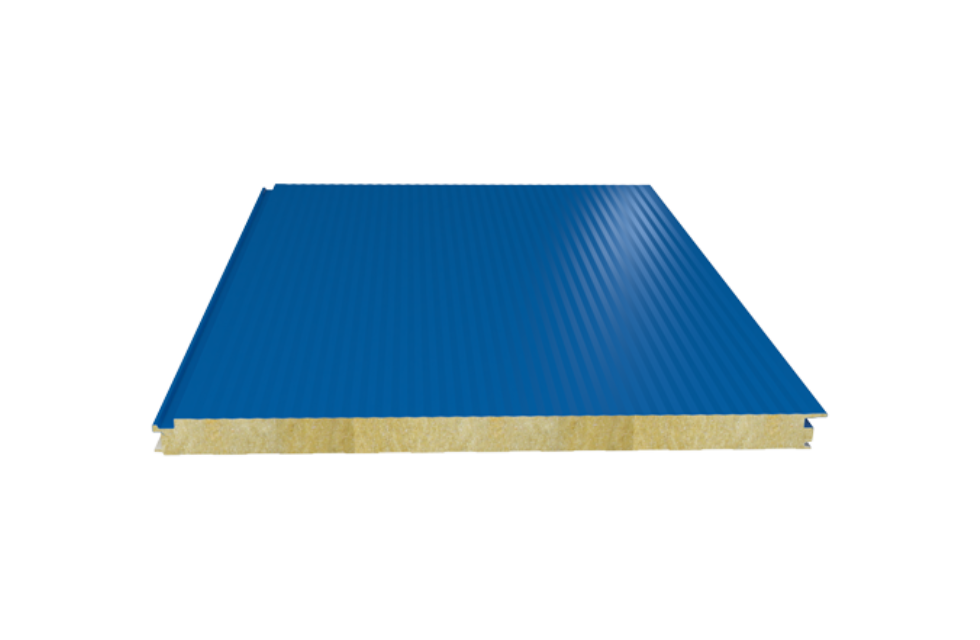

Sandwich panels

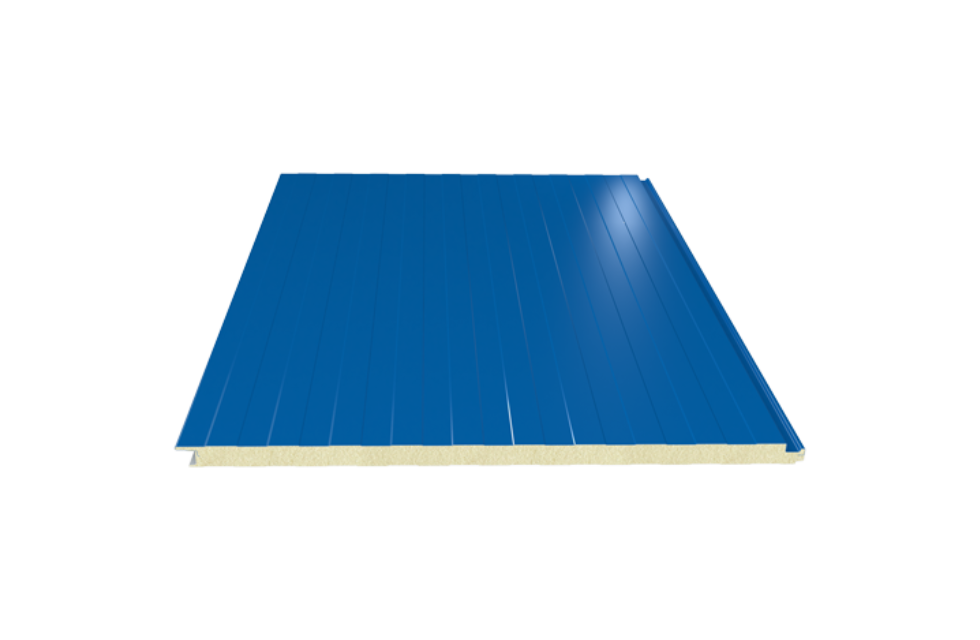

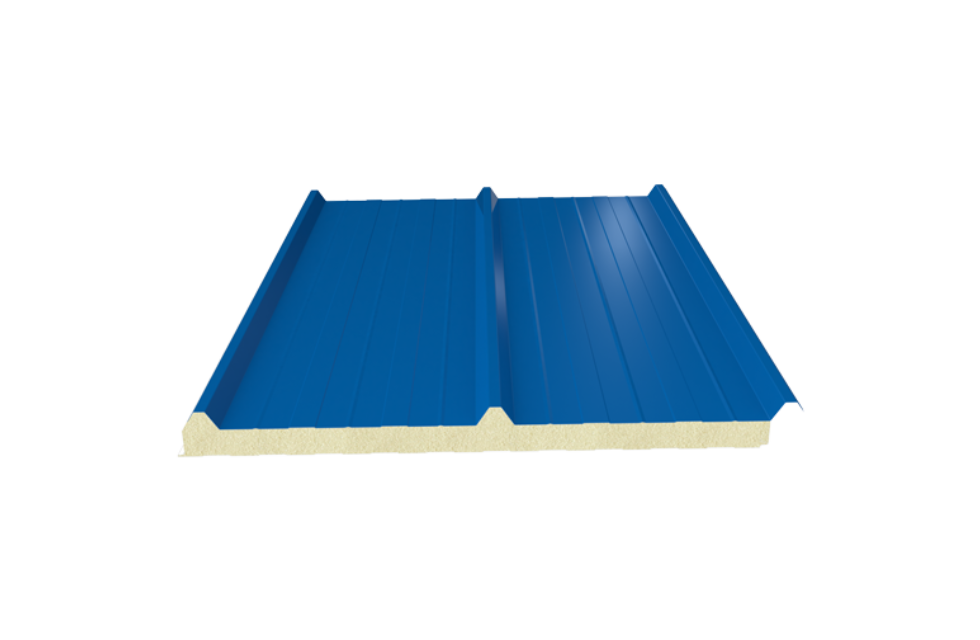

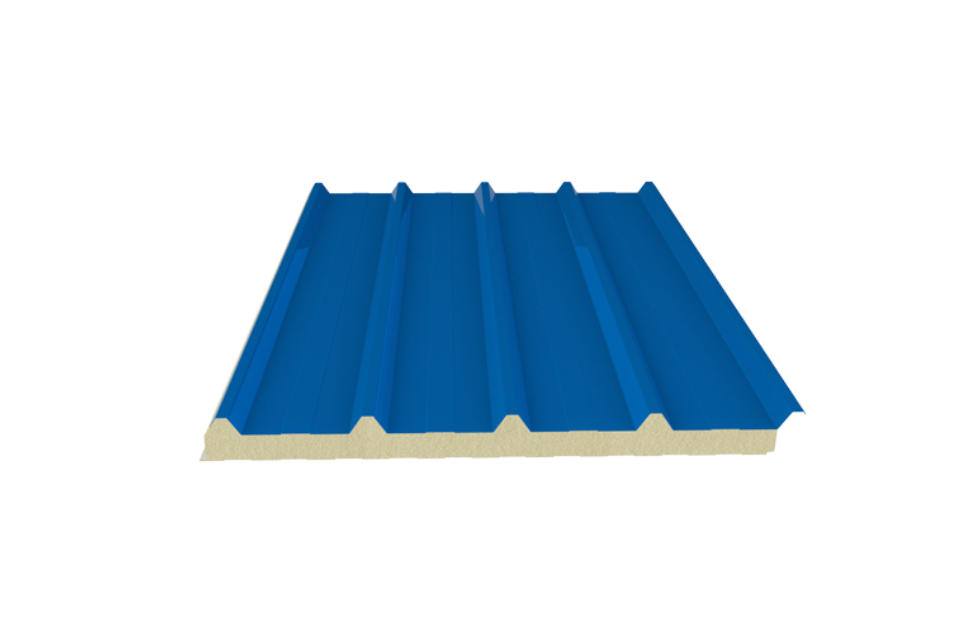

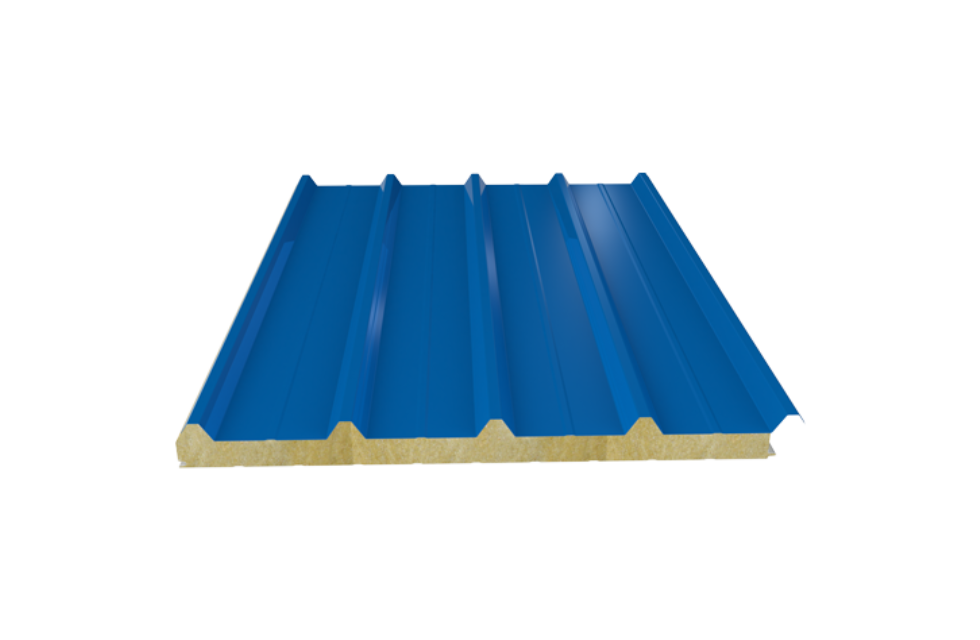

Sendviç panellər müasir tikinti sahəsində geniş istifadə olunan çox funksiyalı materiallardır. Bu panellər binaların dam və divar örtüyü üçün ideal bir seçimdir, çünki həm funksional, həm də estetik cəhətdən üstünlüklərə malikdir

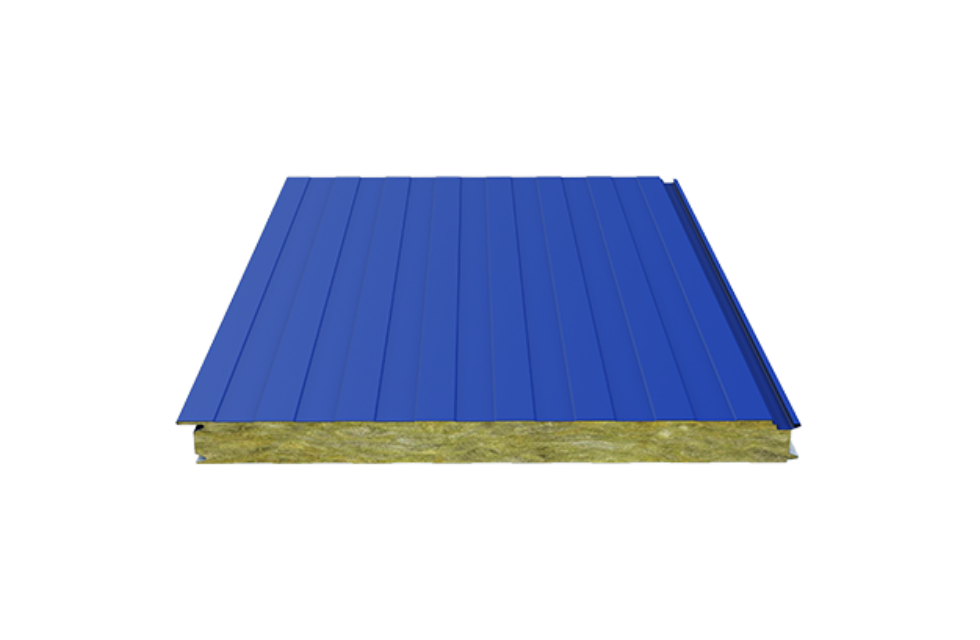

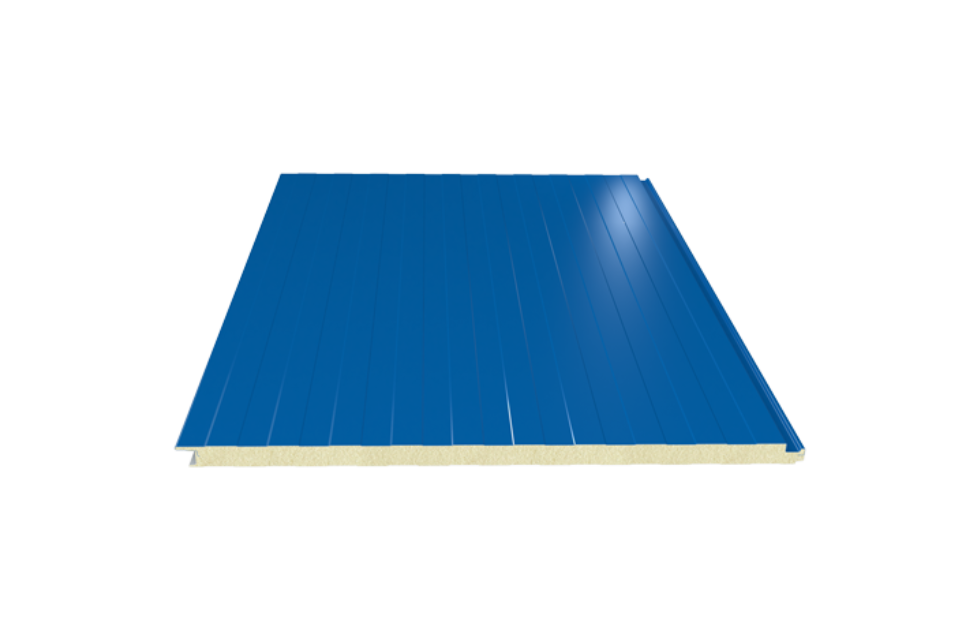

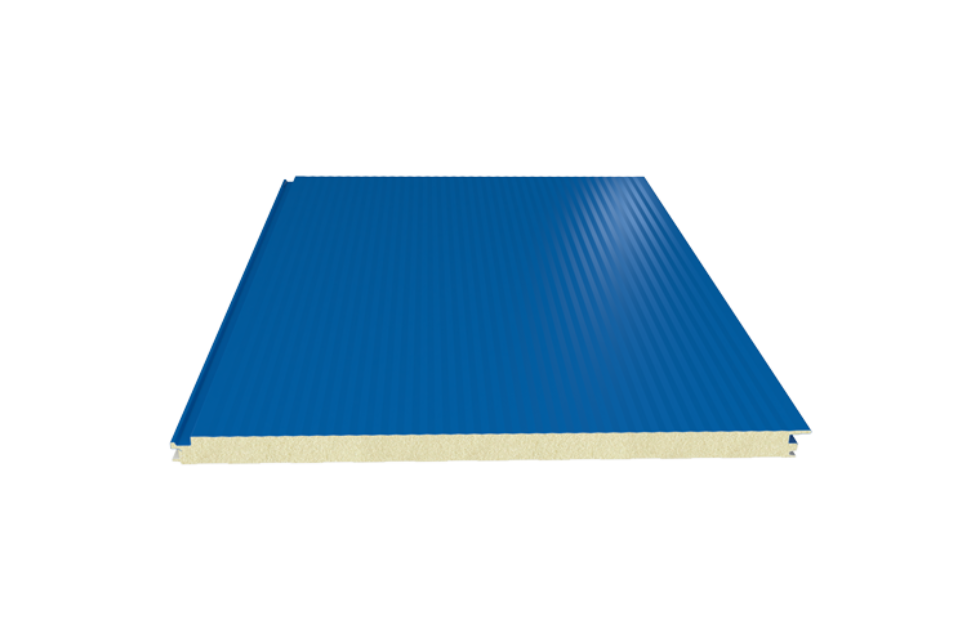

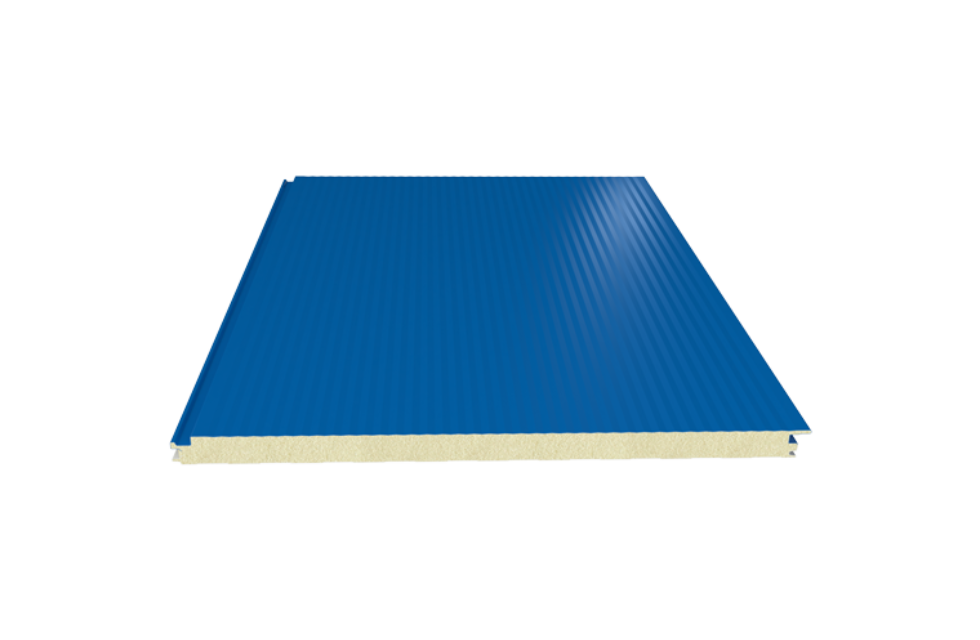

Sendviç panellər əsasən yüksək keyfiyyətli materiallardan hazırlanır və müxtəlif təbəqələrdən ibarət olur. Sendviç panel məhsulların istehsalında 0.3-0.5mm qalınlıqda olan polimer örtüklü polad lövhələrdən və PUR, PIR və daş yunu olmaqla müxtəlif izolyasiya təbəqələrindən istifadə edilir. Sendviç panellərin istilik izolyasiyası xüsusiyyəti enerjiyə qənaət etməyə imkan verir. Eyni zamanda, suya və küləyə qarşı dayanıqlı olmaları tikintini xarici təsirlərdən qoruyur. Sendviç panellər yüngül və quraşdırılması asandır, bu da tikinti işlərinin daha sürətli və qənaətli aparılmasını təmin edir.