Size

Value

Sandwich panel thickness (mm)

40, 50, 60, 70, 80, 100, 120

Length of sandwich panel (mm)

2000 - 15000

Effective width of sandwich panel (mm)

1000

Thickness of metal sheet (mm)

0.30, 0.35, 0.40, 0.45, 0.50

Operating temperature range (°C)

(-40) - (+80)

Thermal conductivity (λ−W/mK)

0.022

Density (kg/m3)

41 (±2)

Bending strength (N/mm²)

0.24 - 0.30

Compressive strength – 10% expanded (N/mm²)

0.15 - 0.20

Water absorption (after 168 hours – %)

0.05 - 0.20

Fire resistance rating

B2 (DIN 4102) EI30

Closed Cell Composition (%)

91 - 95

Zinc coating layer (µ)

125 - 200

Paint layer (µ)

40 - 45

Colors of product

Technical specifications

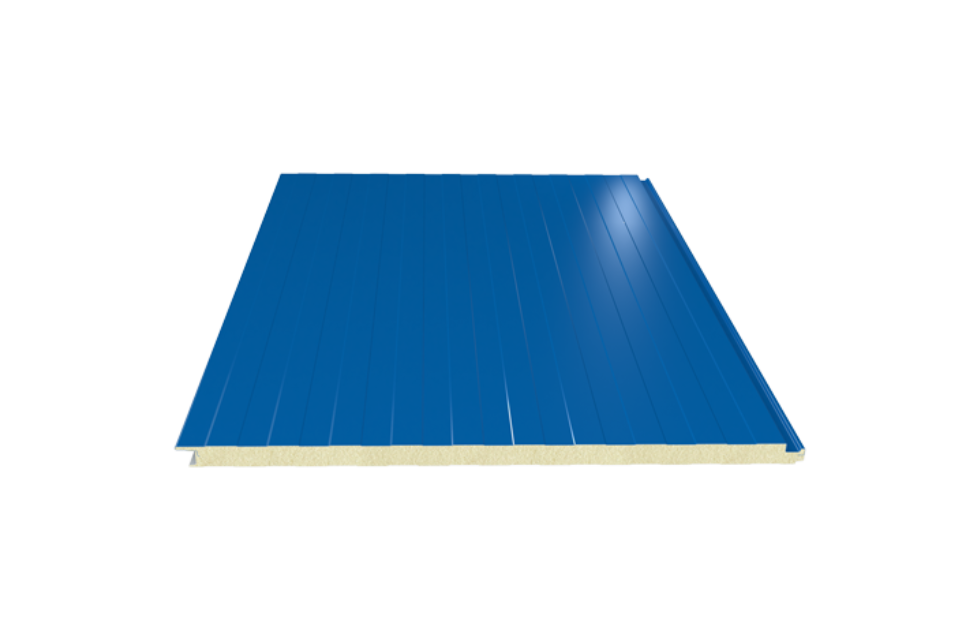

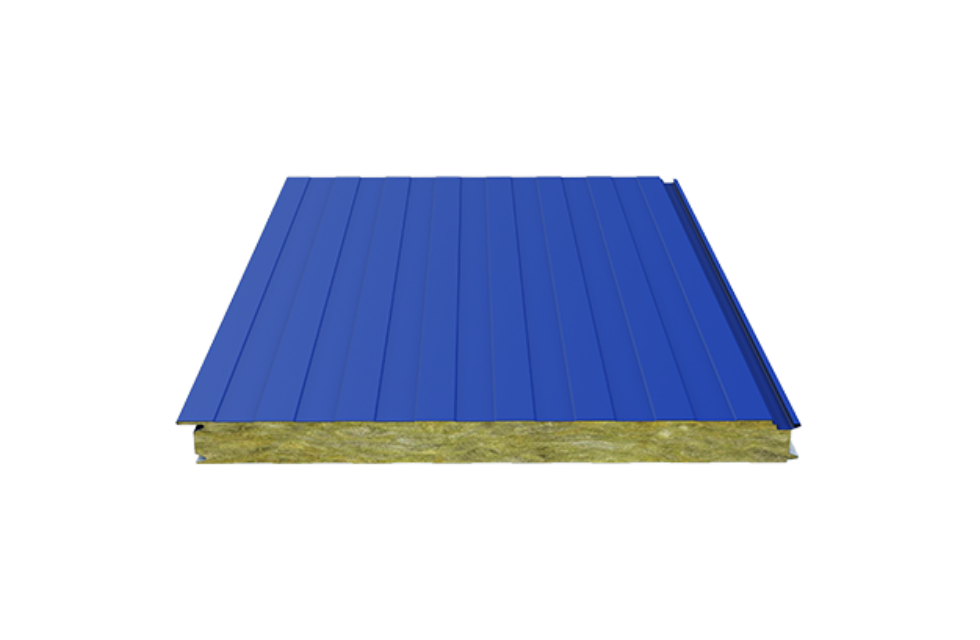

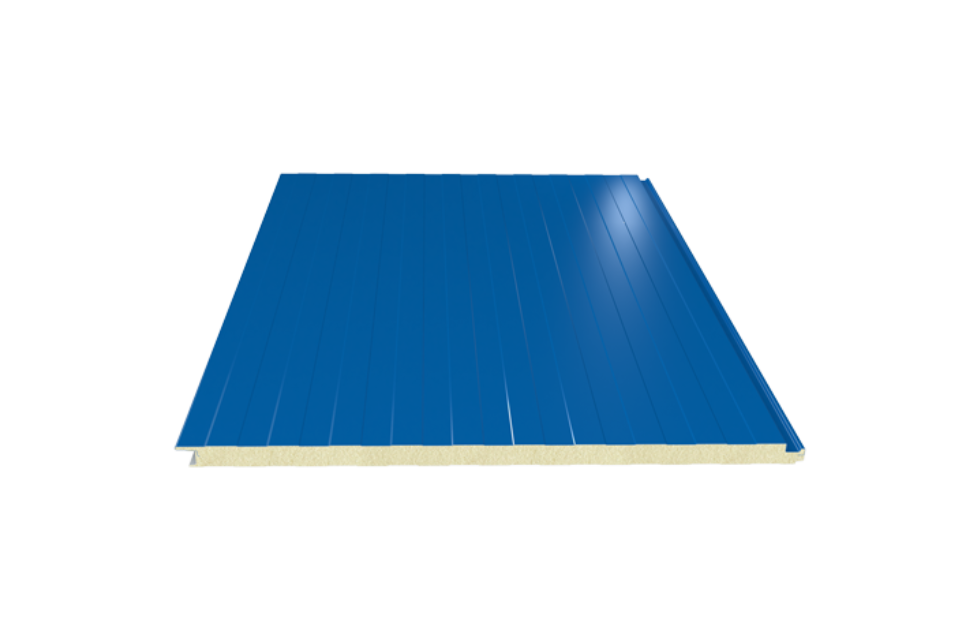

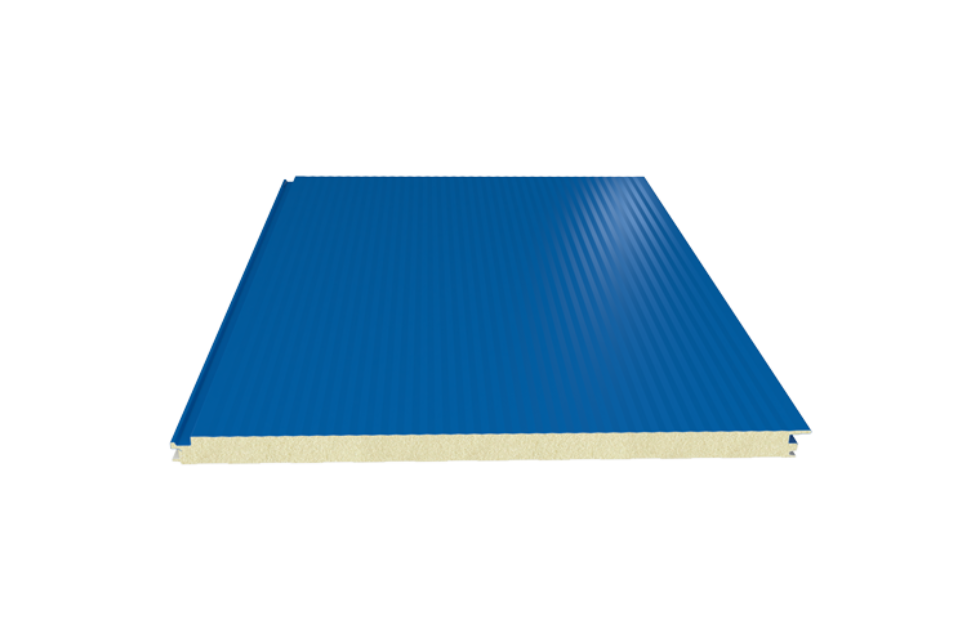

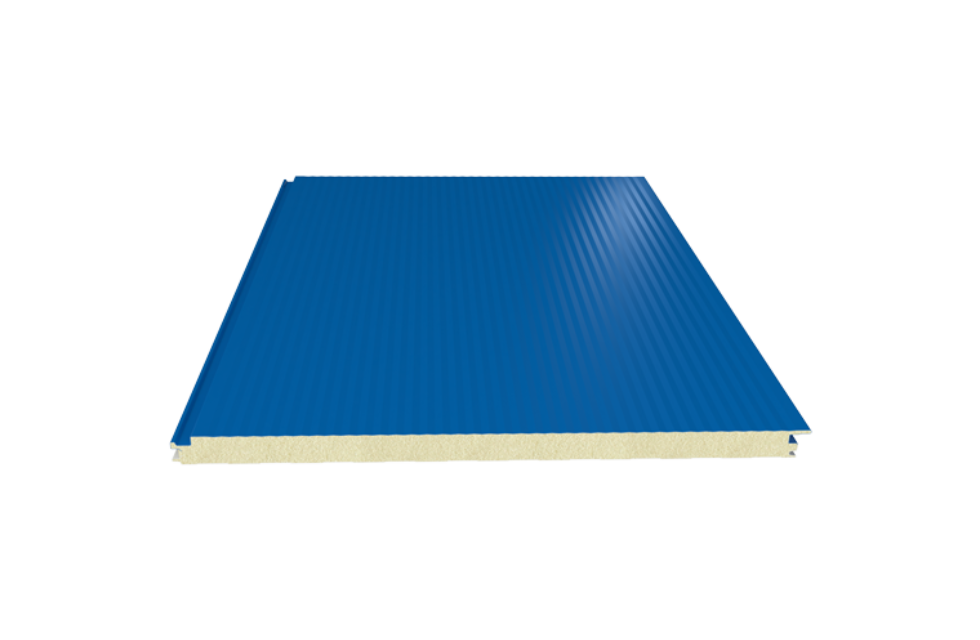

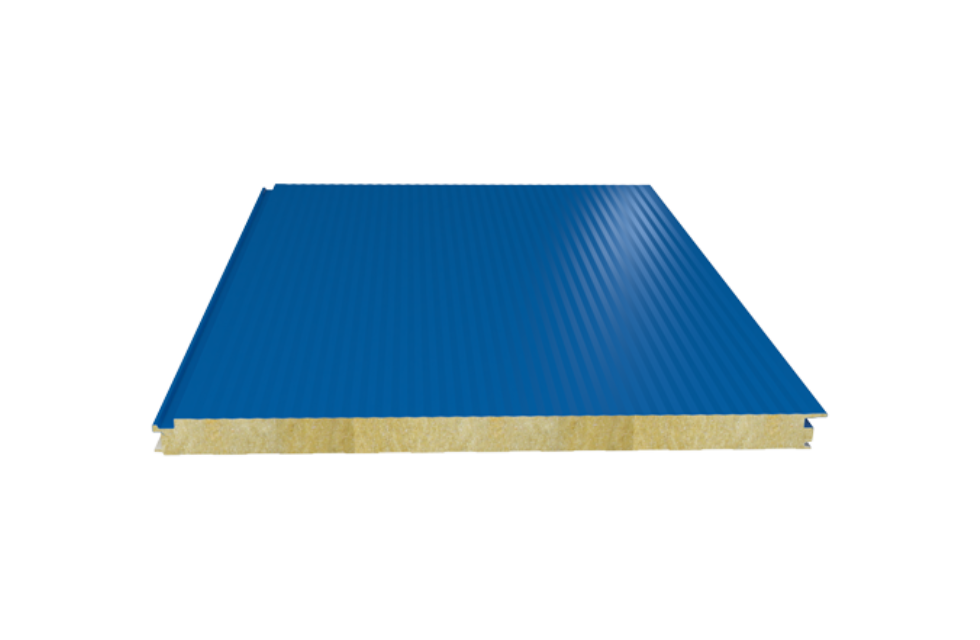

Polyisocyanurate (PIR) Sandwich Wall Panel

PIR-insulated sandwich wall panels are recognized as one of the most innovative and practical solutions in modern construction. They stand out for their superior thermal insulation, fire resistance, and long service life. These panels are used across a wide range of projects — from industrial buildings and commercial facilities to residential homes and agricultural structures.

Each panel is made of two galvanized steel sheets with a polymer coating (thickness 0.3–0.5 mm, width 1090 mm or 1150 mm) and a rigid PIR (polyisocyanurate) insulation core in between. This material resists catching fire and helps slow down the spread of flames, offering a safe and reliable solution.

Key Features

- High thermal insulation

PIR panels significantly reduce heat loss and cooling demand, improving overall energy efficiency. - Fire resistance

The PIR core can withstand high temperatures and produces very little smoke in case of fire, making it a safe choice for a wide range of buildings. - Durability

Resistant to mechanical impacts, moisture, and corrosion, ensuring long-term performance in various conditions. - Lightweight structure

Easy to handle and install, PIR panels reduce the structural load on the building. - Eco-friendly

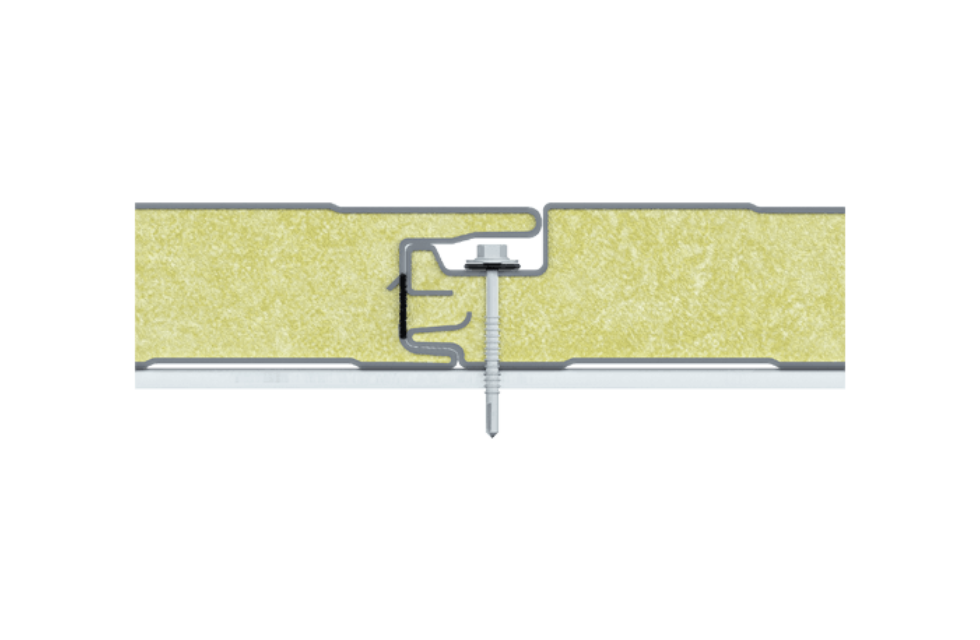

Manufactured using environmentally safe materials with minimal impact on nature. - Hidden fastening system

Panels are joined using a concealed screw system, creating a clean and seamless exterior finish.

Advantages

- Energy savings

Excellent insulation reduces energy consumption and lowers long-term operational costs. - Safety

High fire resistance makes these panels suitable for both industrial and residential projects. - Longevity

Designed to withstand corrosion and environmental stress for many years without degradation. - Quick and easy installation

Lightweight design and interlocking system speed up installation and reduce labor time. - Flexible design options

Available in a variety of colors and textures to fit any architectural style.

Areas of Application

PIR sandwich wall panels are ideal for:

- Industrial buildings

- Warehouses

- Office spaces

- Agricultural structures

- Cold storage and refrigeration facilities

They perform reliably in all types of climates and meet the demanding standards of modern construction.

Why Choose PIR Panels?

PIR-insulated panels offer not only technical advantages but also financial benefits. They improve energy efficiency and help reduce both construction and operational costs. Their fire resistance and clean appearance make them an essential part of any modern building project.

By choosing PIR sandwich wall panels for your project, you ensure safety, durability, and compliance with today’s building standards.