Types of coating of sandwich panels

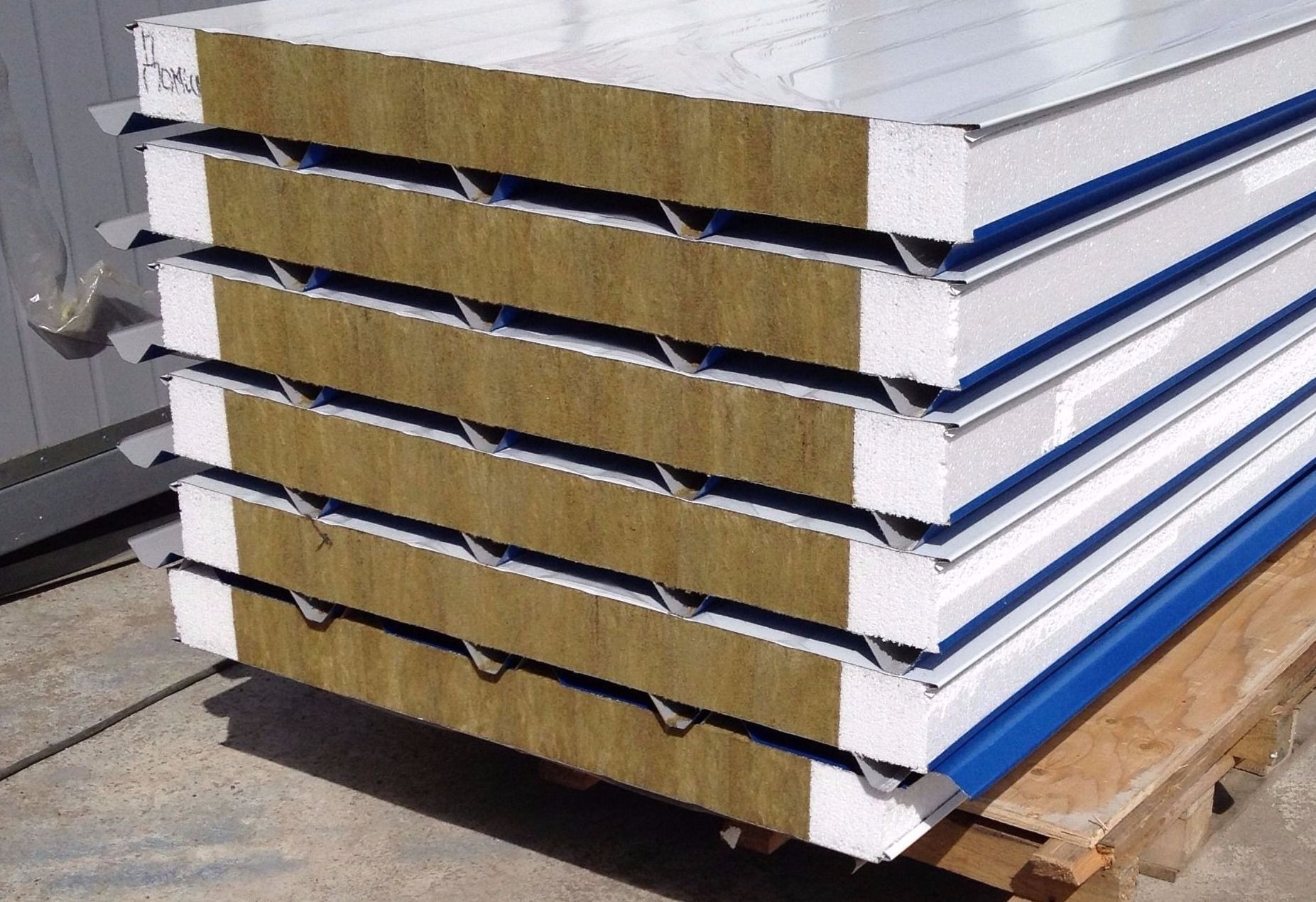

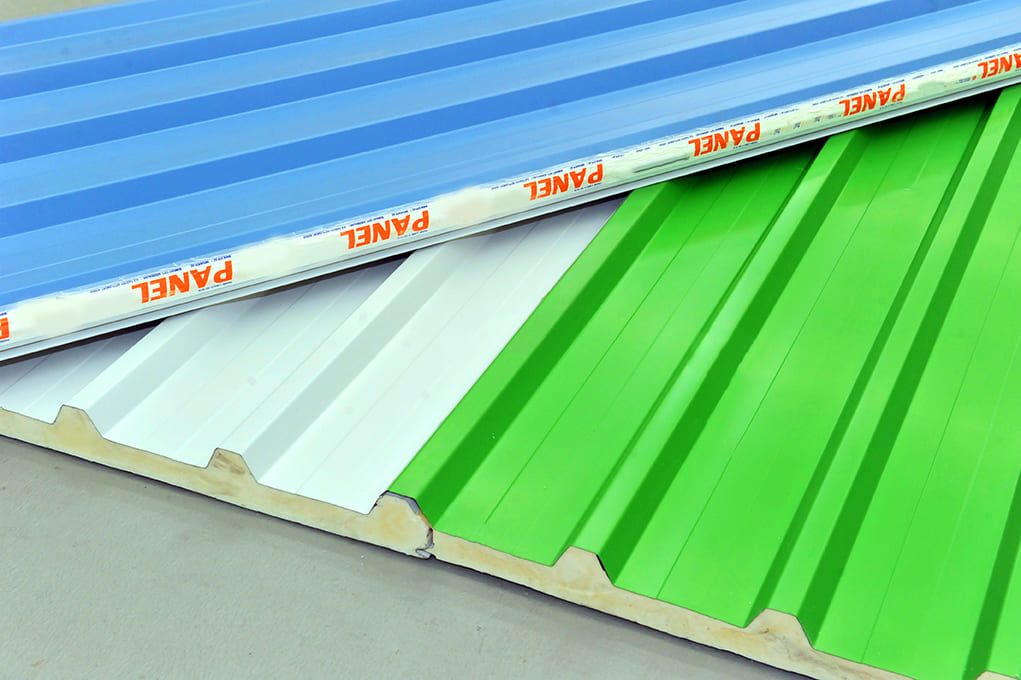

Just as sandwich panels have different types according to their field of use, there are also a wide variety of coating options according to the purpose of these panels: metal-coated, PVC-coated, drywall, plywood, wood or chipboard-coated, paper-coated.

The metal coating surfaces of sandwich panels consist of a combination of metal plate, galvanized and organic coating. The applied orgnic coating plays a special role in increasing the corrosion resistance of the Sendic panel.

Sandwich panels, according to the type of polymer coating, are divided into several varieties, including polister (PE), plastisol, polydifluorionate (PVF2), PVC and polyurethane.

The polyster coating provides high resistance to the outside Impact Factor, elasticity and the right temperature regulation. It is considered the most widely used type of paint. It can be used for different purposes in indoor and outdoor spaces.

PVdF stands out for being highly resistant to chemical oils and UV light. It is widely applied in facade cladding.

Polyurethane is resistant to temperature changes, corrosive and aggressive substances, ultraviolet radiation.

Plastisol has the ability to get the desired perfect shape. It is resistant to moisture and abrasions. It is distinguished by its high performance in cold and humid climates.

PVC is applied by the lamination method. This species, which has high elasticity, is hygienic and can be easily cleaned.

Sandwich panels with a metal coating of superior quality are produced by the Uniprocurement company, taking into account all existing rules.

Blog

Subscribe to our newsletter