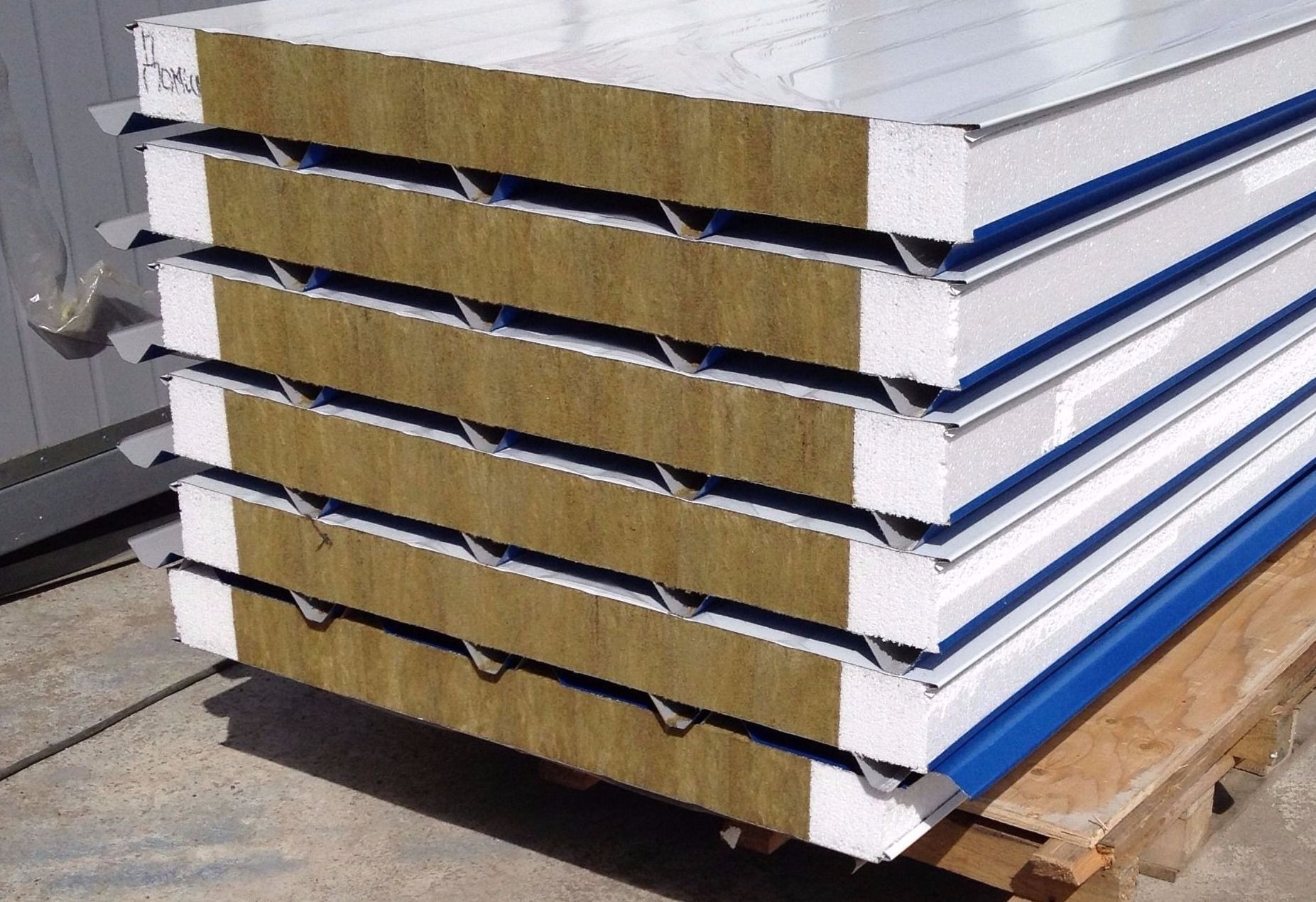

Sandwich panel houses

The development of technology in recent times has a huge impact on new construction solutions. In the construction industry, sandwich panel is considered the optimal solution for residential projects with outstanding characteristics compared to traditional materials. However, houses made of this material have advantages, as well as some disadvantages. We have collected the pros and cons for you in this article:

Easy and quick setup

The Panel is pre-assembled in a ready-made form, so installation is quick and convenient. This, in turn, helps to speed up the project and shorten the construction time to builders by a third.

Cost savings

Using a sandwich panel during home construction can save up to 20% on investment costs, in addition to ensuring the quality of work. Sandwich panel houses are up to 40% lighter than traditional building materials.

Along with the listed features, the advantages of these houses include sound, thermal insulation, aesthetic appearance and hotel, school building, country house, etc. a wide range of applications can be noted as.

Among all these, as well as a number of negative features of sandwich panel houses, it is known that some types of panels have high temprature intolerance and are resistant only to temperatures from 35 to 75 degrees.

And the unfavorable horizontal carrying capacity is another of them. The sandwich panel does not have successful performance in polygonal architectural structures, as pre-fabricated foam panels and wire mesh cannot be bent or cut easily.

Also, water resistance is not good, so it is not considered appropriate to use it under a wall or in a place where there is contact with water.

Blog

Subscribe to our newsletter