Size

Value

Sandwich panel thickness (mm)

50, 70, 80, 100, 120

Length of sandwich panel (mm)

2000 - 15000

Effective width of sandwich panel (mm)

1000

Thickness of metal sheet (mm)

0.45, 0.50

Thermal stability

(-170) - (+700)

Thermal conductivity (λ−W/mK)

0.035 - 0.045

Density (kg/m3)

100 (±10)

Fire resistance rating

A2 s1 d0 (TS EN 13501-1)

Colors of product

Technical specifications

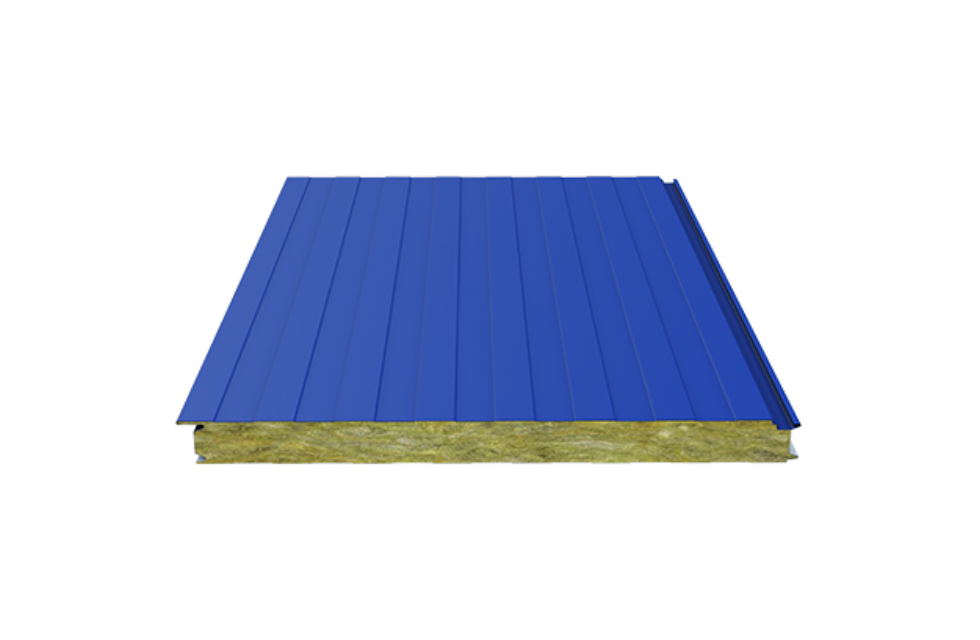

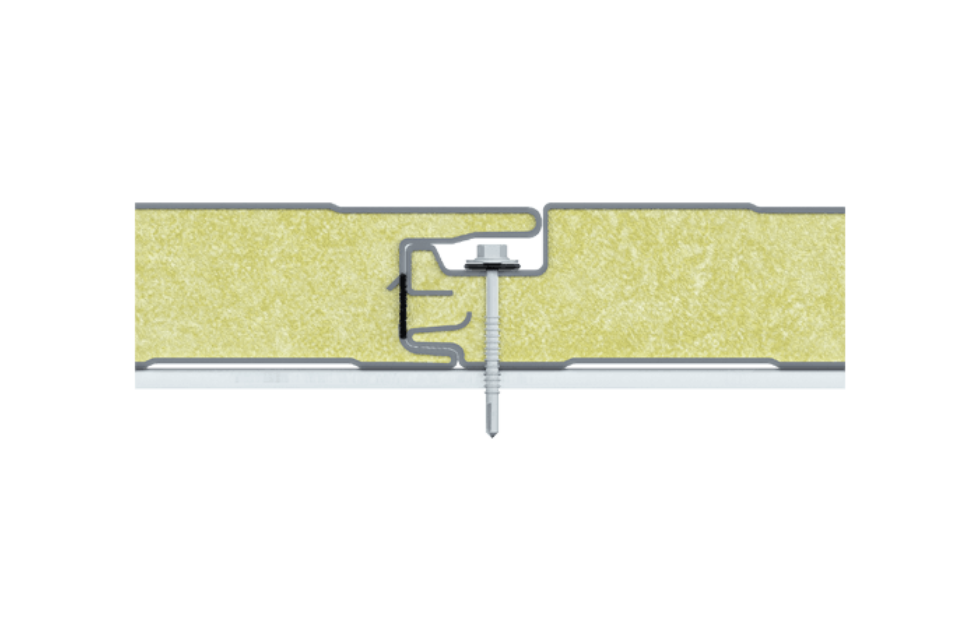

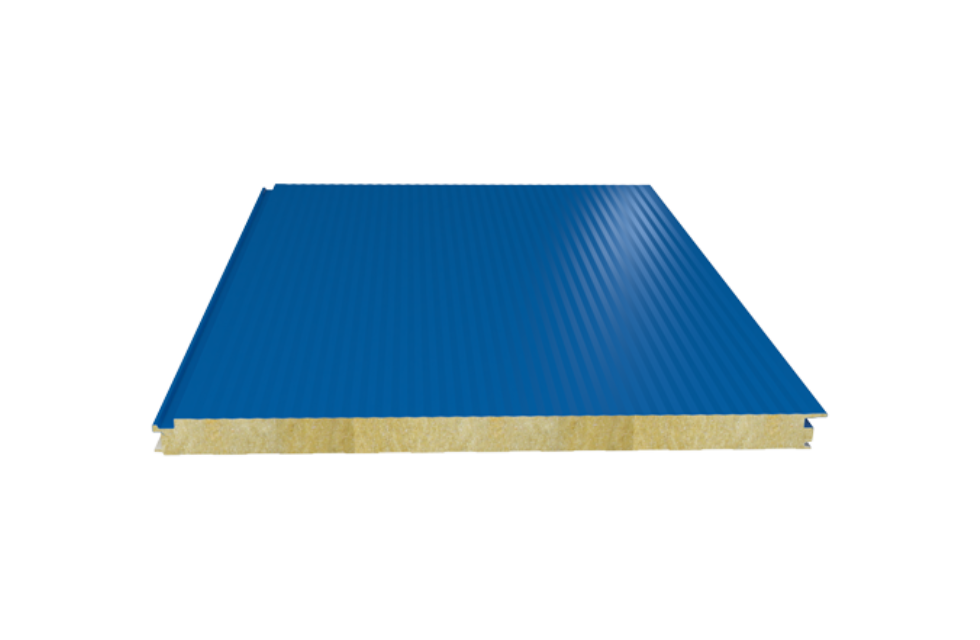

Sandwich Wall Panel with Stone Wool

Stone wool is obtained by melting inorganic raw materials (basalt rock) at 1350-1400°C and transforming them into fibers. The panel dimensions remain unchanged even under conditions of high humidity: they do not rot, mold, rust, or corrode. They are not affected by insects and microorganisms. In our fully automated production plant, stone wool plates are divided into sections to fill the inner part by placing them perpendicular to the panel surface, thereby increasing the sandwich panel’s compression strength. Stone wool provides sound and thermal insulation and a high level of fire safety.

Stone wool wall panel application areas

Stone wool wall panels have a wide range of applications. They are used in commercial and residential buildings, industrial complexes, warehouses, and agricultural structures. The versatility of our stone wool panels ensures their easy installation in both new construction and repair projects.