Size

Value

Sandwich panel thickness (mm)

40, 50, 60, 70, 80, 100, 120

Length of sandwich panel (mm)

2000 - 15000

Effective width of sandwich panel (mm)

1000

Thickness of metal sheet (mm)

0.30, 0.35, 0.40, 0.45, 0.50

Operating temperature range (°C)

(-40) - (+80)

Thermal conductivity (λ−W/mK)

0.022

Density (kg/m3)

41 (±2)

Bending strength (N/mm²)

0.24 - 0.30

Compressive strength – 10% expanded (N/mm²)

0.15 - 0.20

Water absorption (after 168 hours – %)

0.05 - 0.20

Fire resistance rating

B2 (DIN 4102) EI30

Closed Cell Composition (%)

91 - 95

Zinc coating layer (µ)

125 - 200

Paint layer (µ)

40 - 45

Colors of product

Technical specifications

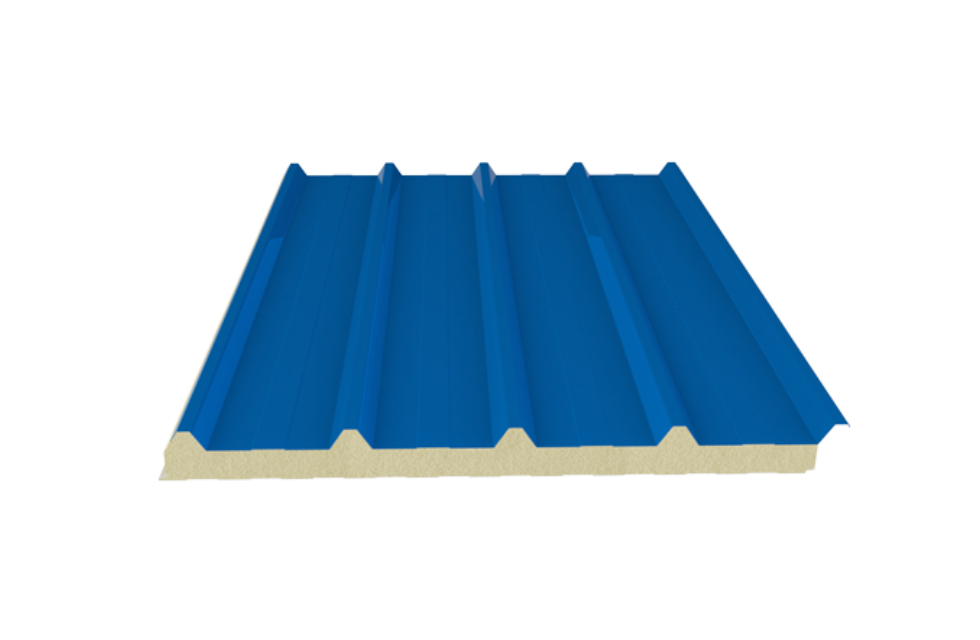

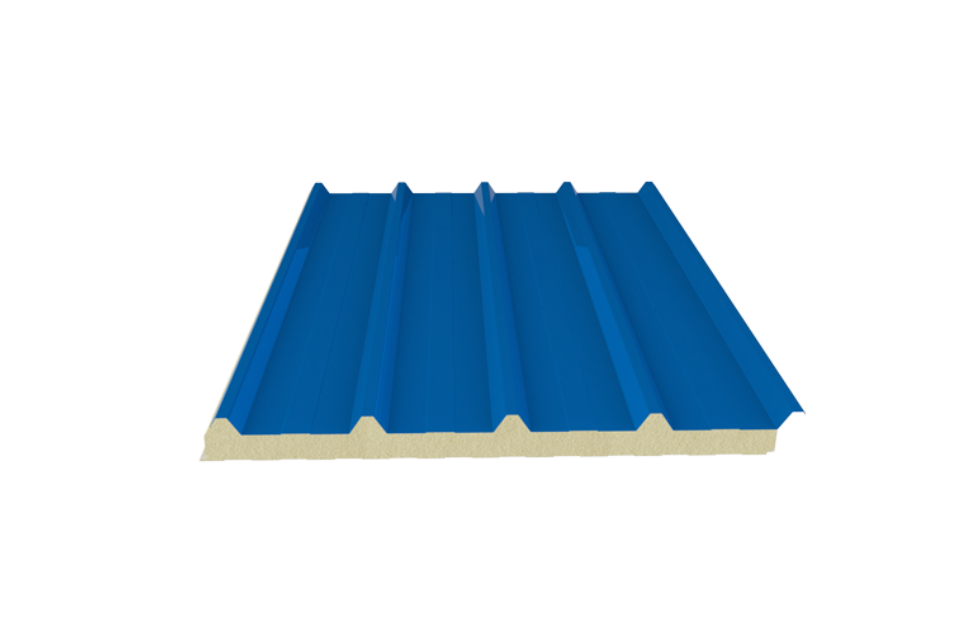

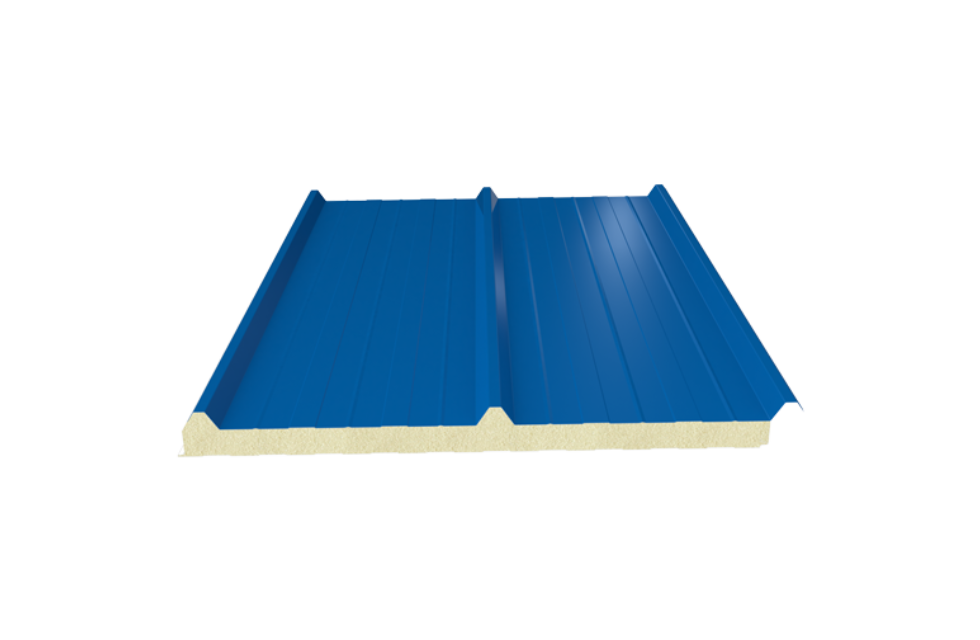

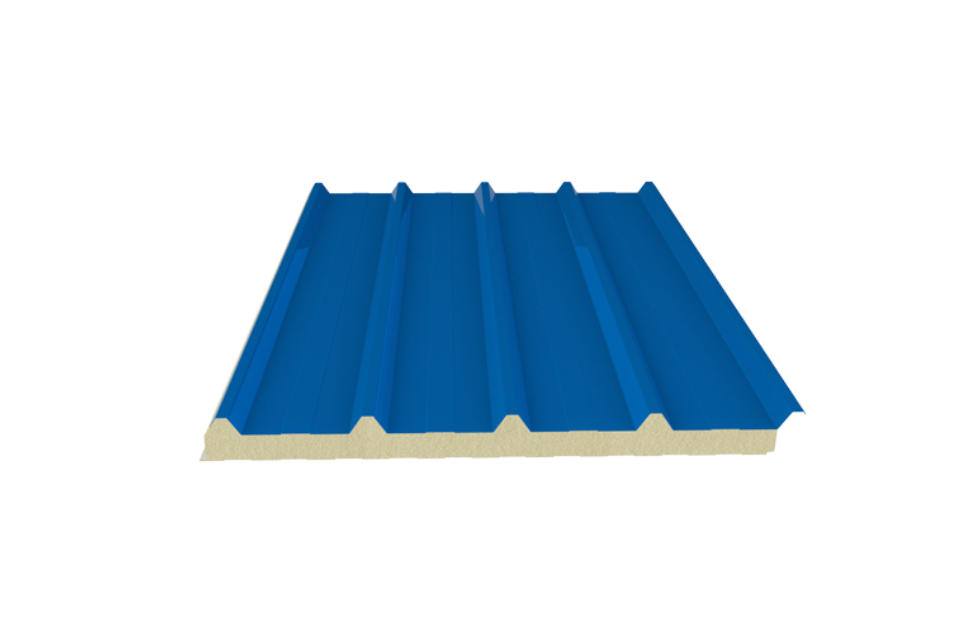

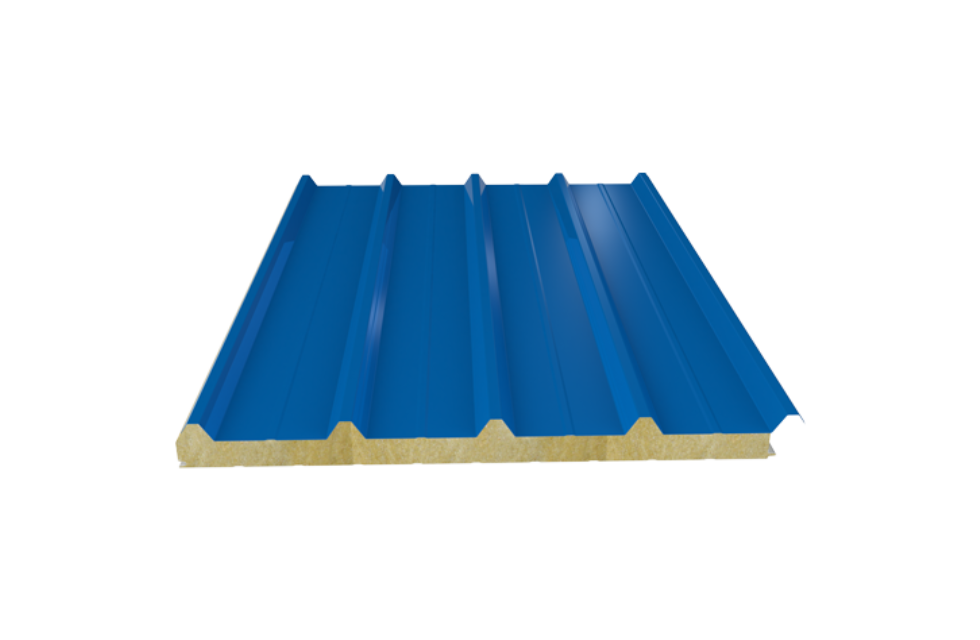

5-rib Roof Sandwich Panel with Polyisocyanurate (PIR)

The PIR-insulated sandwich roof panel with a 5-rib profile is an innovative and practical solution in modern construction. Thanks to its excellent thermal and acoustic insulation, high fire resistance, mechanical strength, and clean design, it meets a wide range of building requirements and is widely used in various sectors.

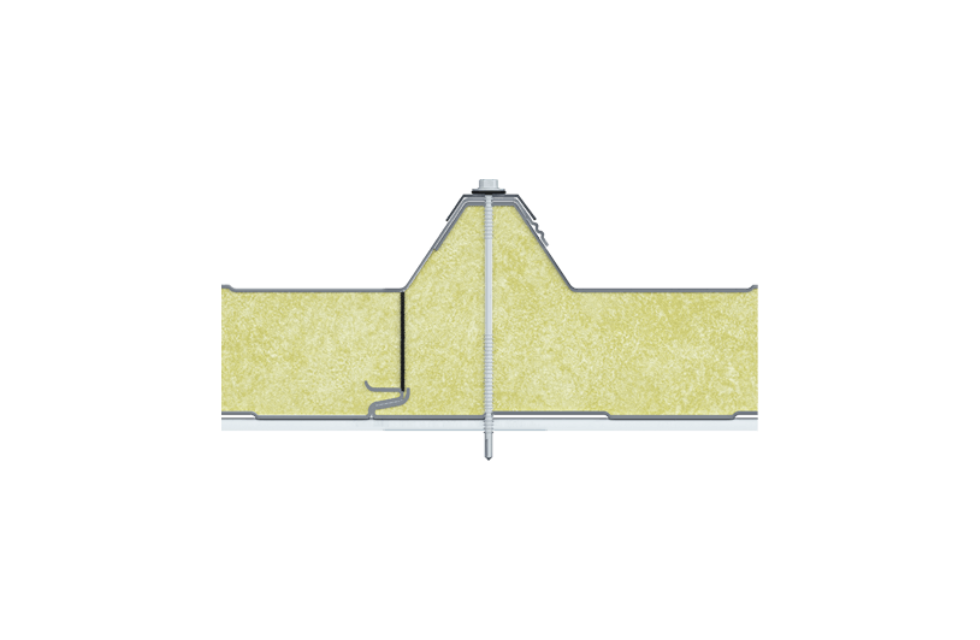

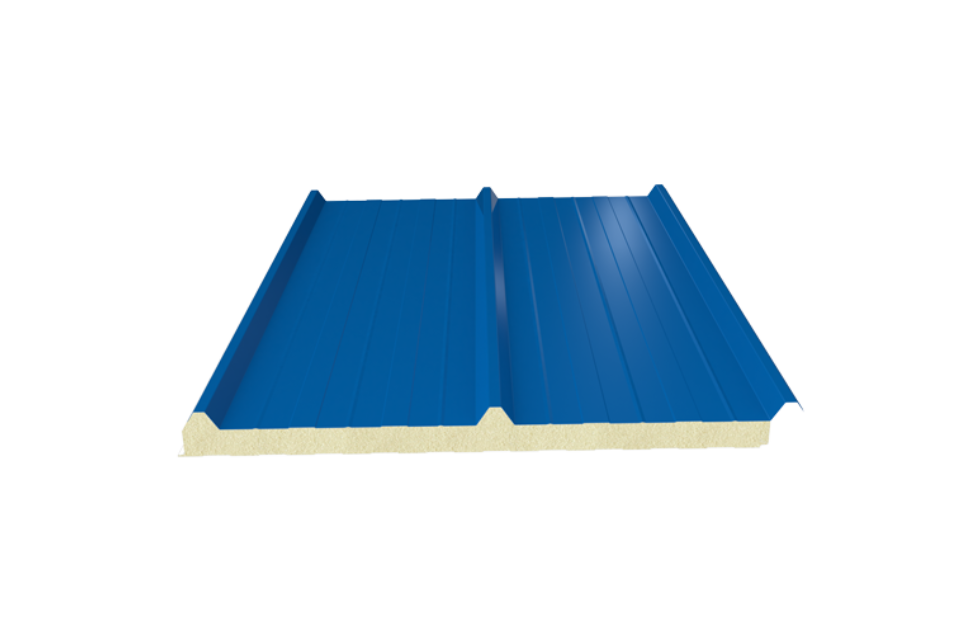

The panel is made of two galvanized steel sheets with a polymer coating (thickness: 0.3–0.5 mm; width: 1090 mm or 1200 mm), with a core of rigid PIR (polyisocyanurate) foam between them. PIR provides superior fire resistance and is classified as a flame-retardant material.

Key Features

- High Thermal Insulation

The PIR core has very low thermal conductivity, which significantly reduces energy loss and increases the energy efficiency of the building. - Fire Resistance

PIR helps reduce fire risk and slows down flame spread, making it an ideal solution for safety-critical applications. - 5-Rib Profile

The top surface of the panel features a 5-rib design that increases structural strength and adds a modern, uniform look. - Strong and Durable

The panel can withstand wind, snow, and external forces, offering reliable performance even in tough weather conditions. - Sound Insulation

The structure helps block external noise, creating better indoor acoustic comfort. - Lightweight Construction

The panel is easy to transport and install, helping reduce labor costs and installation time.

Main Benefits

- Energy Efficiency

Helps reduce heating and cooling costs by minimizing heat transfer. - Long-Term Durability

The panels do not deform over time and remain effective even in harsh climates. - Fire Protection

PIR core provides excellent fire resistance, enhancing overall building safety. - Attractive Appearance

The 5-rib surface combines strength with a modern and neat look. - Quick and Easy Installation

Simplifies the construction process and lowers total project costs.

Areas of Application

- Industrial buildings: factories, warehouses, production facilities

- Commercial properties: offices, shopping centers, showrooms, hotels

- Residential buildings: villas, multi-story apartment blocks, private homes

- Agricultural facilities: farms, greenhouses, grain storage units

Five-rib sandwich roof panels with a polyisocyanurate (PIR) core stand out in modern construction projects for their high technical performance and long-term durability. With advantages such as aesthetic design, fire resistance, and energy efficiency, these panels are an ideal choice for various industrial and residential buildings. Structures built with PIR roof panels are safer, more functional, and cost-effective.