Size

Value

Sandwich panel thickness (mm)

40, 50, 60, 70, 80, 100, 120

Length of sandwich panel (mm)

2000 - 15000

Effective width of sandwich panel (mm)

1000

Thickness of metal sheet (mm)

0.30, 0.35, 0.40, 0.45, 0.50

Operating temperature range (°C)

(-40) - (+80)

Thermal conductivity (λ−W/mK)

0.022

Density (kg/m3)

40 (±2)

Bending strength (N/mm²)

0.24 - 0.30

Compressive strength – 10% expanded (N/mm²)

0.15 - 0.20

Water absorption (after 168 hours – %)

0.05 - 0.20

Fire resistance rating

B2 (DIN 4102) EI30

Closed Cell Composition (%)

91 - 95

Zinc coating layer (µ)

125 - 200

Paint layer (µ)

40 - 45

Colors of product

Technical specifications

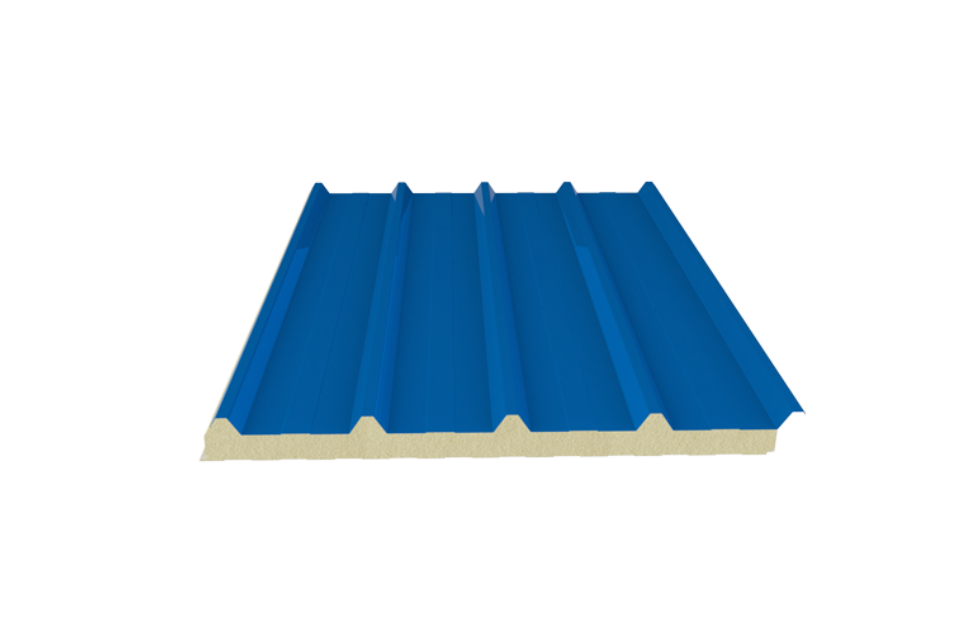

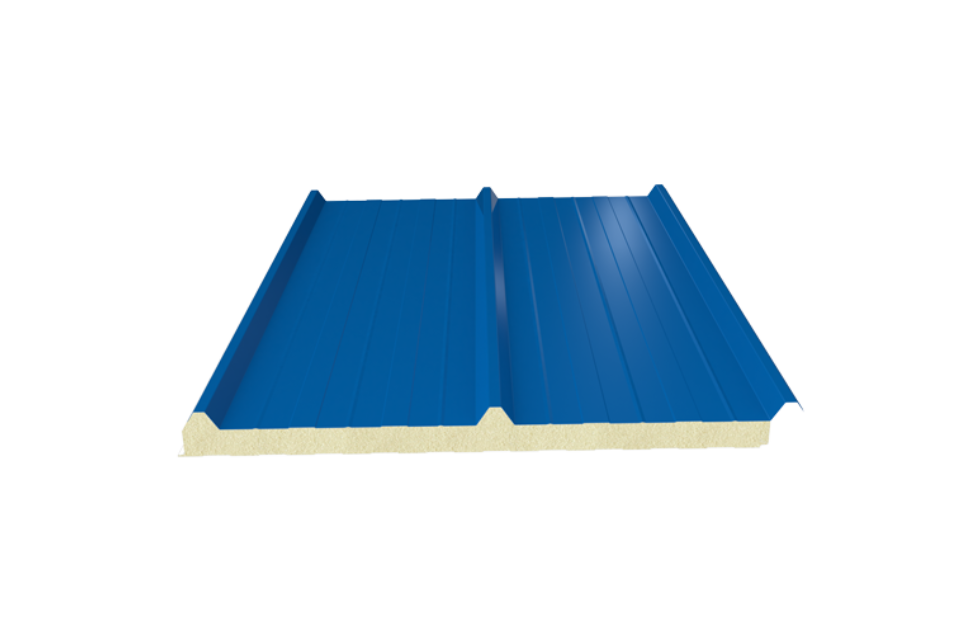

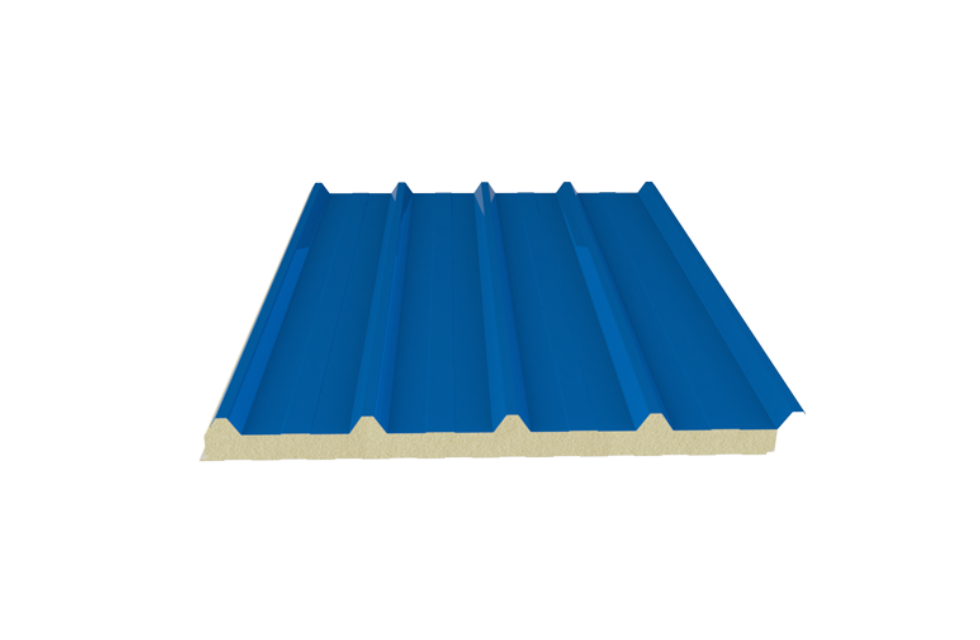

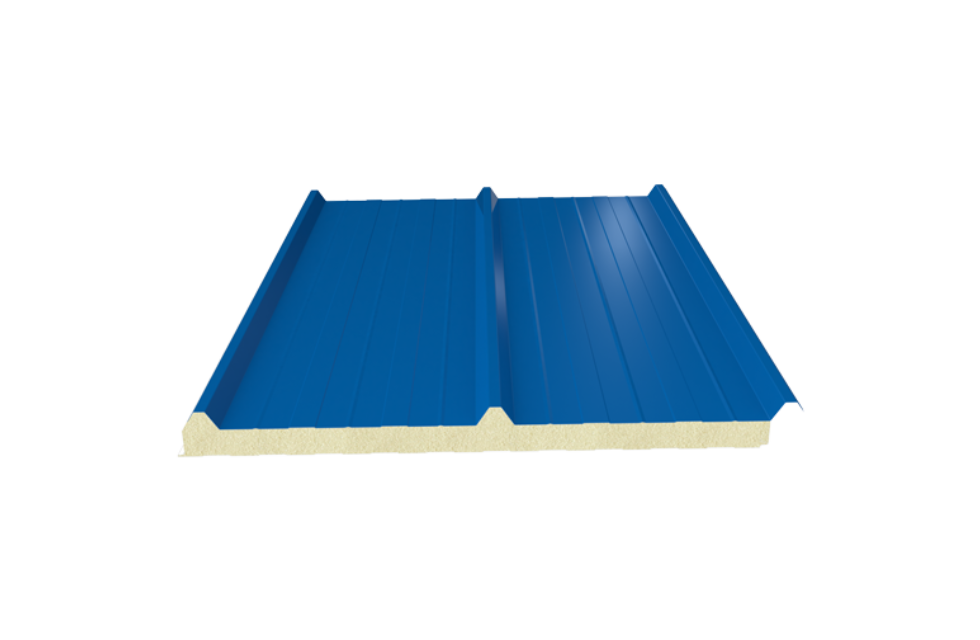

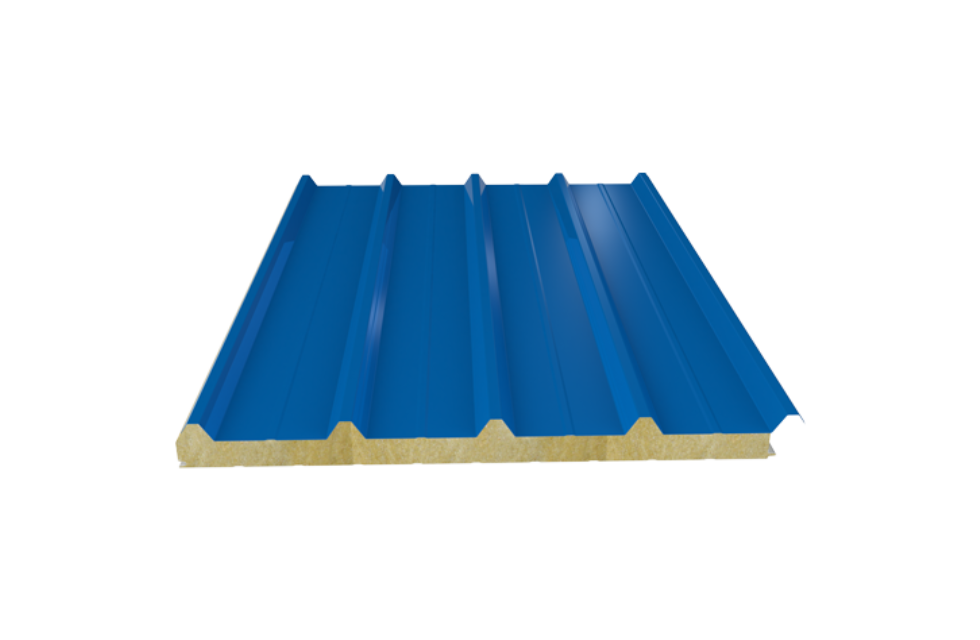

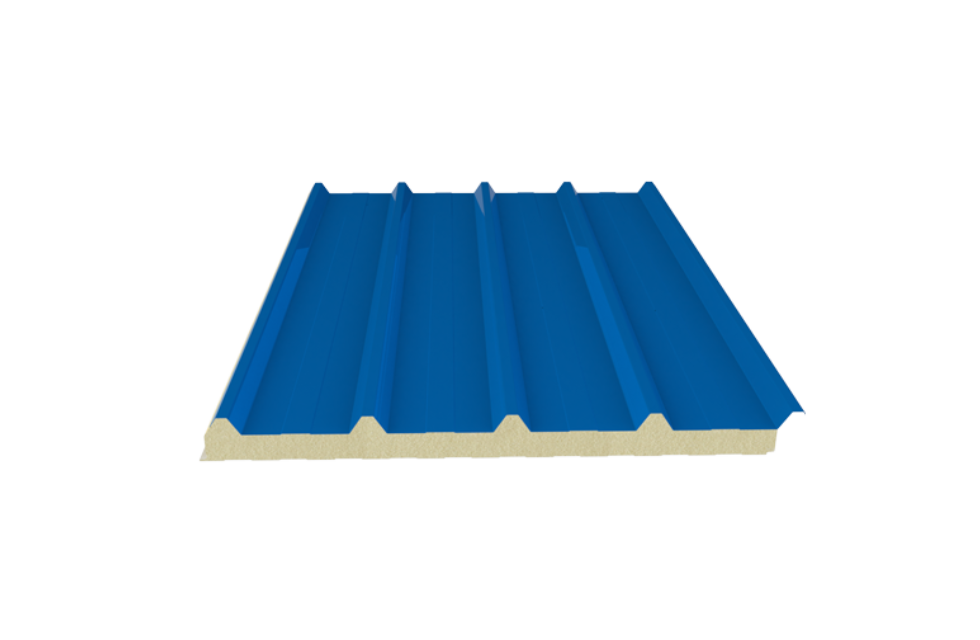

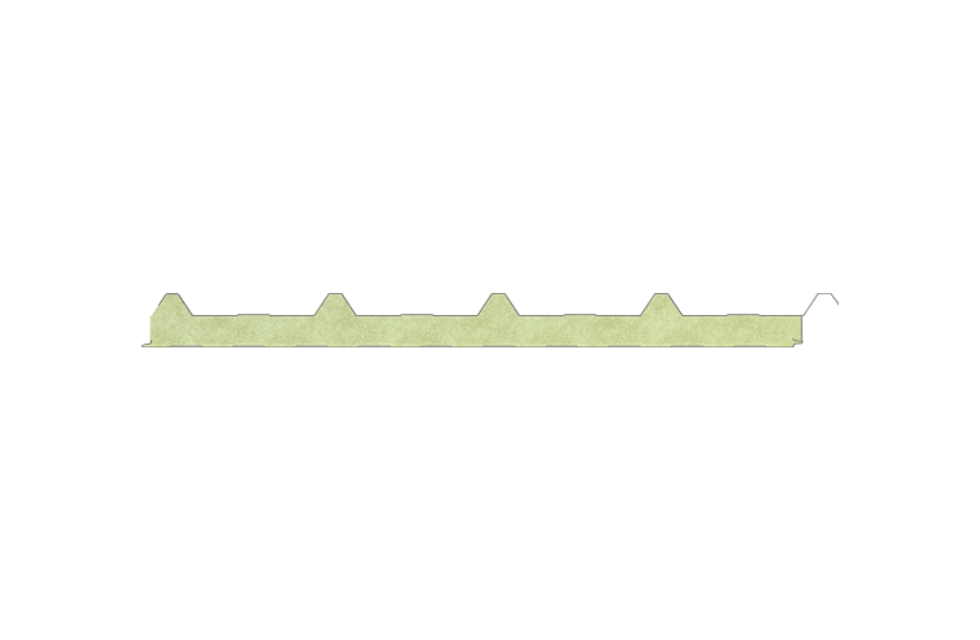

5-rib Roof Sandwich Panel with Polyurethane (PUR)

For those looking for efficient, durable, and energy-saving solutions in modern construction, 5-rib sandwich roof panels with a polyurethane (PUR) core are the perfect choice. Manufactured to high quality standards, these panels are widely used in residential, industrial, and commercial buildings. Their technical specifications and advantages deliver maximum value for a wide range of projects.

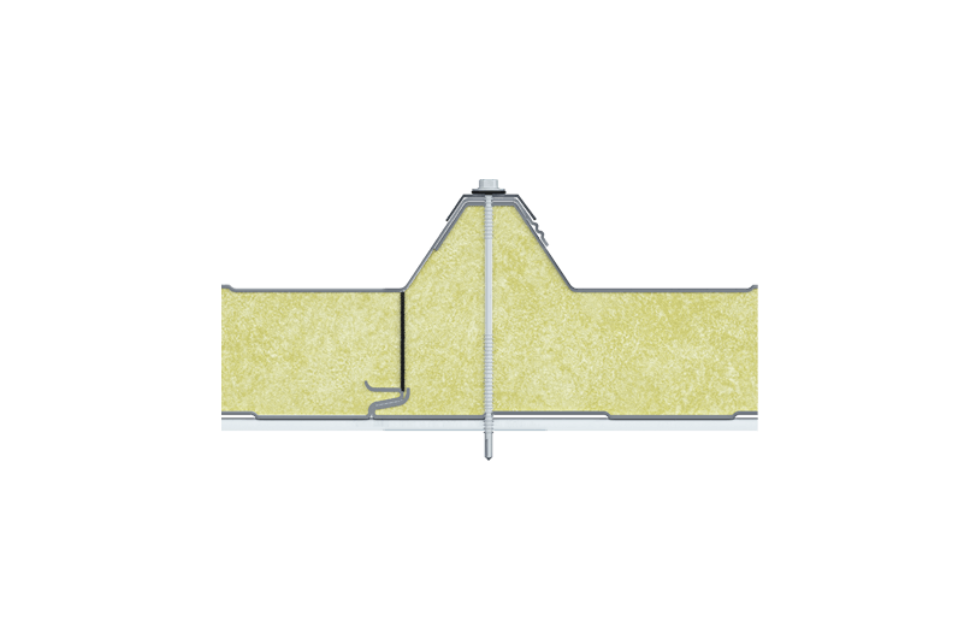

The panels are constructed with two galvanized steel sheets coated with polymer (thickness: 0.3–0.5 mm, width: 1090 mm or 1200 mm) and a rigid polyurethane insulation layer between them. The polyurethane core provides good fire resistance and falls under the B2 fire classification.

Key Features

- 5-Rib Design

The specially designed 5-rib profile provides additional strength and load-bearing capacity, ensuring the safety of the roof even under extreme weather conditions. - High-Performance Insulation

The PUR core delivers excellent thermal and sound insulation, helping to significantly reduce energy costs. - Superior Waterproofing

Thanks to its special structure, the panel offers complete protection against moisture and prevents leaks. - Lightweight Construction

The panel’s lightweight nature simplifies transportation and installation processes. - Fire Resistance

The PUR insulation makes the panels resistant to ignition, improving the fire safety of the building. - Long-Term Durability

Exceptional physical and chemical properties ensure the panels maintain their performance for many years.

Advantages

- Outstanding Thermal and Acoustic Insulation

The combination of the 5-rib structure and PUR insulation guarantees maximum protection against heat loss in winter and keeps interiors cooler in summer. - Economic Efficiency

Low maintenance requirements and durable materials make these panels a cost-effective solution over the long term. - Fast Installation

The modular design allows for quick and easy assembly, helping to speed up construction timelines. - Modern Aesthetic Appearance

A variety of colors and design options add both functional and visual value to any project. - Environmental Friendliness

PUR is an environmentally safe material with minimal impact on the environment.

5-rib PUR-insulated sandwich roof panels are a modern, high-performance, and multifunctional product manufactured in accordance with today's construction standards. They are an indispensable solution for industrial facilities, residential buildings, and commercial centers. Combining safety, aesthetics, and technical excellence, these panels add significant value to any project.