Loading Sandwich Panels: Points to Consider

Loading Sandwich Panels: Points to Consider

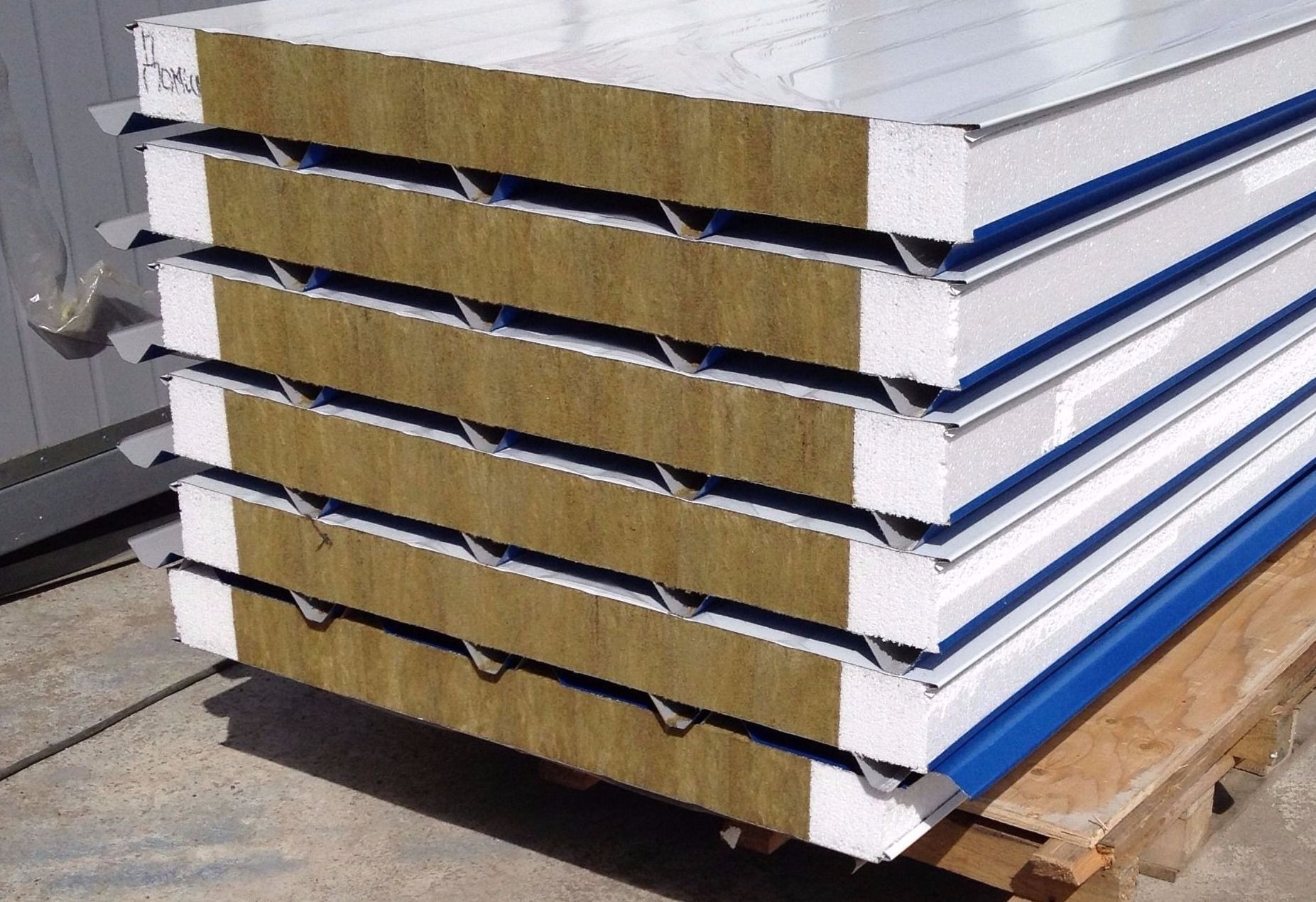

Sandwich panels are widely used in the construction sector as light but durable structural elements. Their proper loading, handling, and unloading are of paramount importance for the preservation of materials and efficient construction processes. In this blog we will review the key points for safe loading of sandwich panels and ways to minimize the risks.

Loading Sandwich Panels: The Right Steps

Following proper procedures during the loading process both preserves product quality and ensures work safety.

Proper sorting of materials: During loading, panels should be sorted according to size and thickness. This helps both to make unloading easier and to prevent damage.

Maintenance of protective layers: The surface of sandwich rings is covered with a special protective layer against corrosion and impacts. Extra precautions must be taken during loading to avoid damaging this layer.

Manual loading or hardware? The use of technical equipment must be preferred during loading. The ends of the panels may be bent or damaged during manual handling.

These key points to consider when loading sandwich panels will help maintain product quality, ensure work safety, and ultimately complete the project on time and successfully.

Blog

Subscribe to our newsletter