Thermal properties of sandwich panels

Universal Procurement is one of the leading companies specializing in the production of sandwich panels of different types and different designations throughout the country.

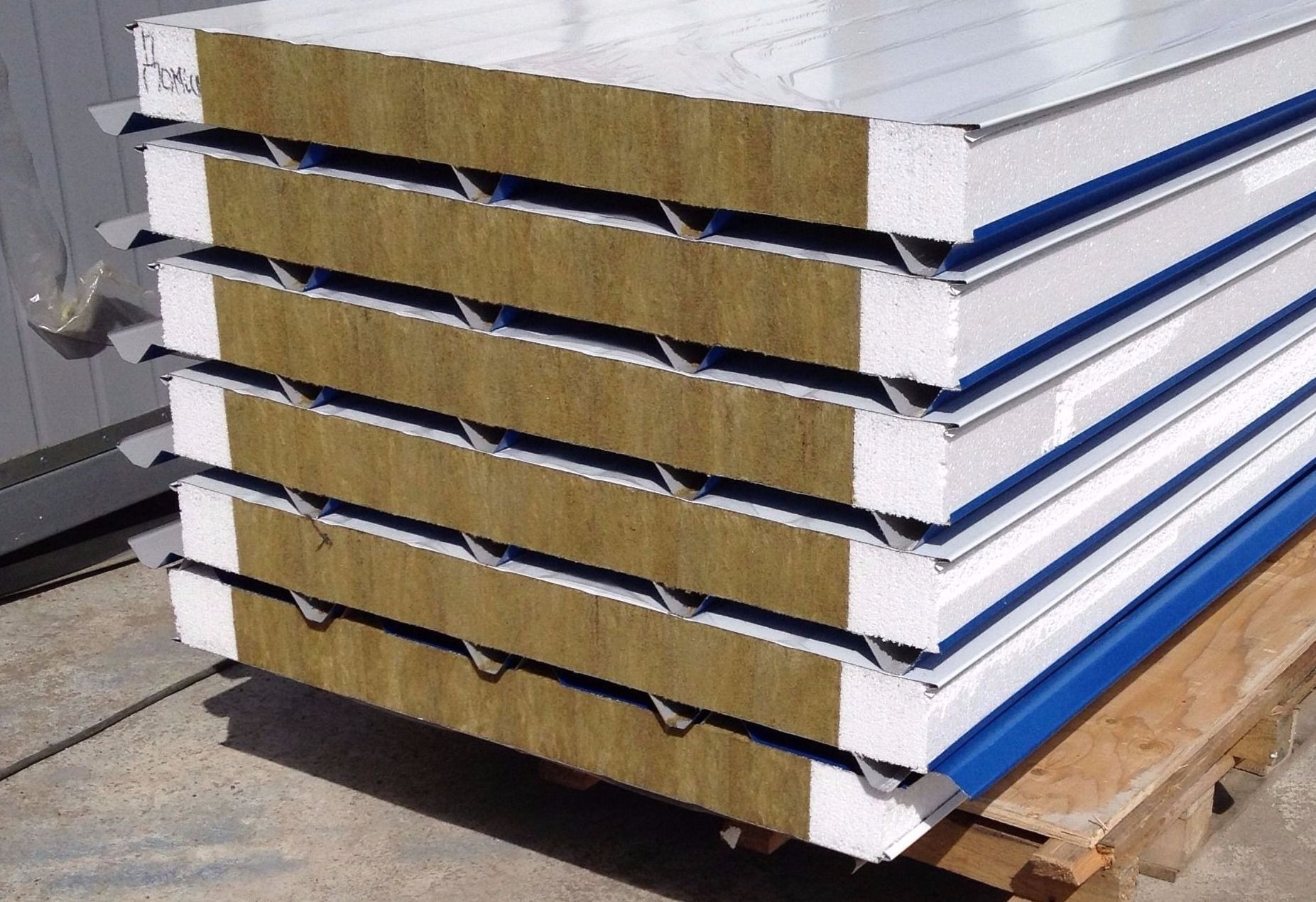

Sandwich panels produced with inner filling material between two painted galvanized or aluminum plates (PIR andpur) are used in roof and facade regions of buildings. Sandwich panels provide exceptionally high heat, water, sound insulation in the space where they are applied and prevent moisture.

Among all these positive properties listed, it is worth noting the fact that sandwich panels are of a composition quite suitable for thermal insulation. Thermal insulation is an important nuance that can be provided in a structure in terms of reducing the energy spent on heating in winter and cooling in summer and creating a comfortable environment.

The application of sandwich panels in the constructed structures prevents problems such as mold, moisture and allows the construction to be long-lasting. The thickness of the insulating materials of sandwich panels is determined in a special way in accordance with the load-bearing potential, climatic conditions, the purpose of use of the structure and other indicators. Polyurethane thicknesses ranging from 30-80 mm are considered standard.

Another important issue to take into account when applying sandwich panels on interior walls is that the temperature difference between the room and the wall is a maximum of 3ºC. Otherwise, unwanted sweating and damping can form on the walls. In order not to experience such situations, the correct calculation of the values required during the application is of paramount importance.

Blog

Subscribe to our newsletter