Sandwich panels

Sandwich panels

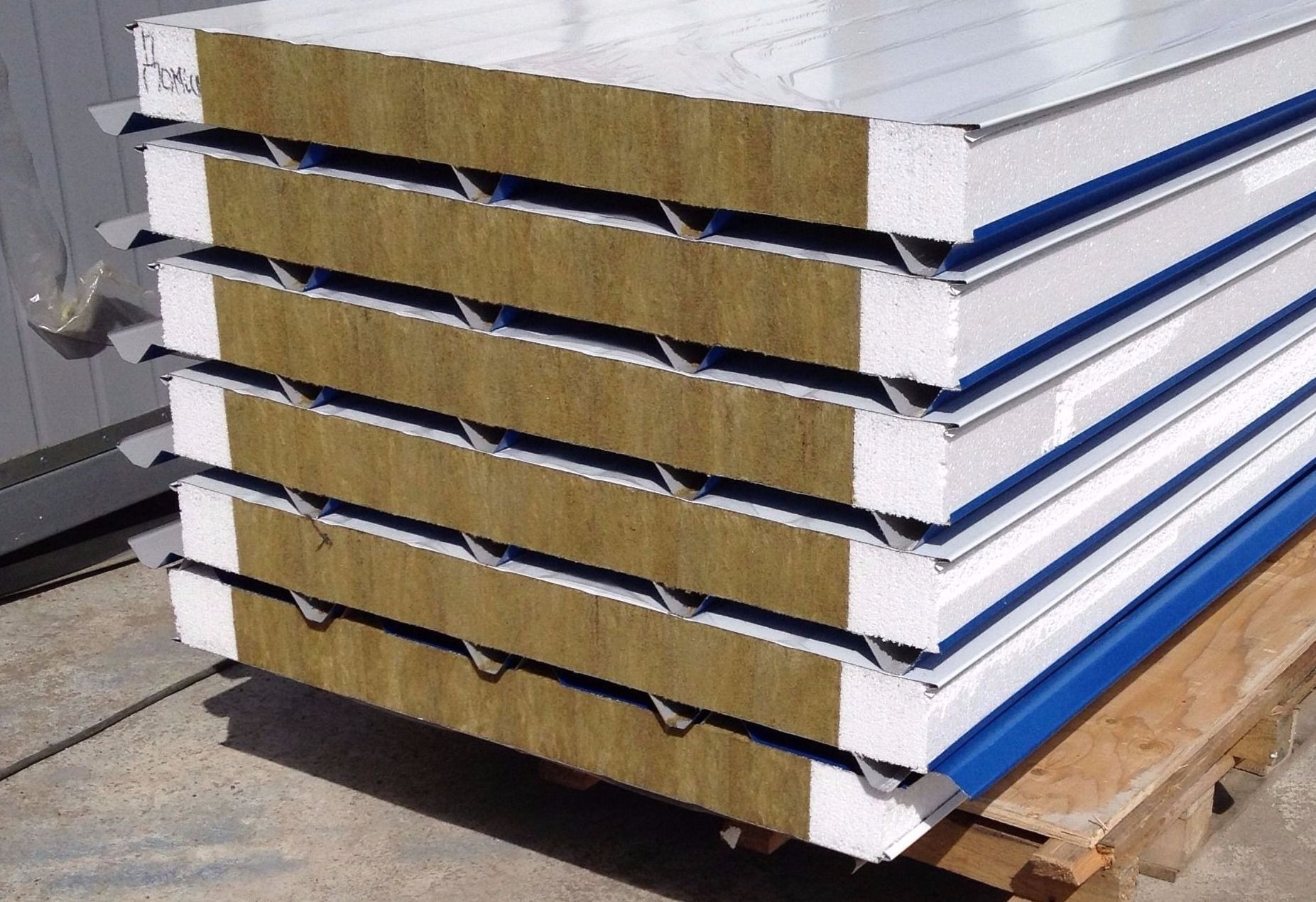

Sandwich panel-a building material, the outer sides of which are made of solid material, most often metal, and the inner side is made of thermal insulation. The Material is used for the construction of kiosks and shops, as well as cinemas and other commercial objects. Warehouses and finished structures are insulated sandwich panels. In addition, it is an excellent soundproofing material that is suitable for creating interior partitions. Supermarkets, shopping centers, cottages and buildings with a height of no more than 2 floors – all this is created from panels.

Types of sandwich panels

According to such a criterion as functional purpose, the following types of panels are distinguished: wall and roofing.

Sandwich panels belonging to the category of wall panels are used in the construction of buildings for various purposes (warehouse, industrial, administrative, commercial and other). In addition, they can be used in the construction of low-rise residential buildings and refrigerators. In the production of these works, protection structures in horizontal and vertical, as well as inclined forms are assembled from the products.

Roofing sandwich panels are used in the construction of roofs. Here we can talk about the construction of buildings and structures of various types. Modern element-type mounting sandwich panels form a separate group. Here they use high-performance thermal insulation, complemented by a galvanized and cooled steel profile and polymer coating. In addition, a wind and water protection system was designed, which makes the structures resistant to extreme climatic influences. The types of Element-type assembly attract not only with wind and rain resistance, but also with good sound insulation, variability of configurations, storage and economy.

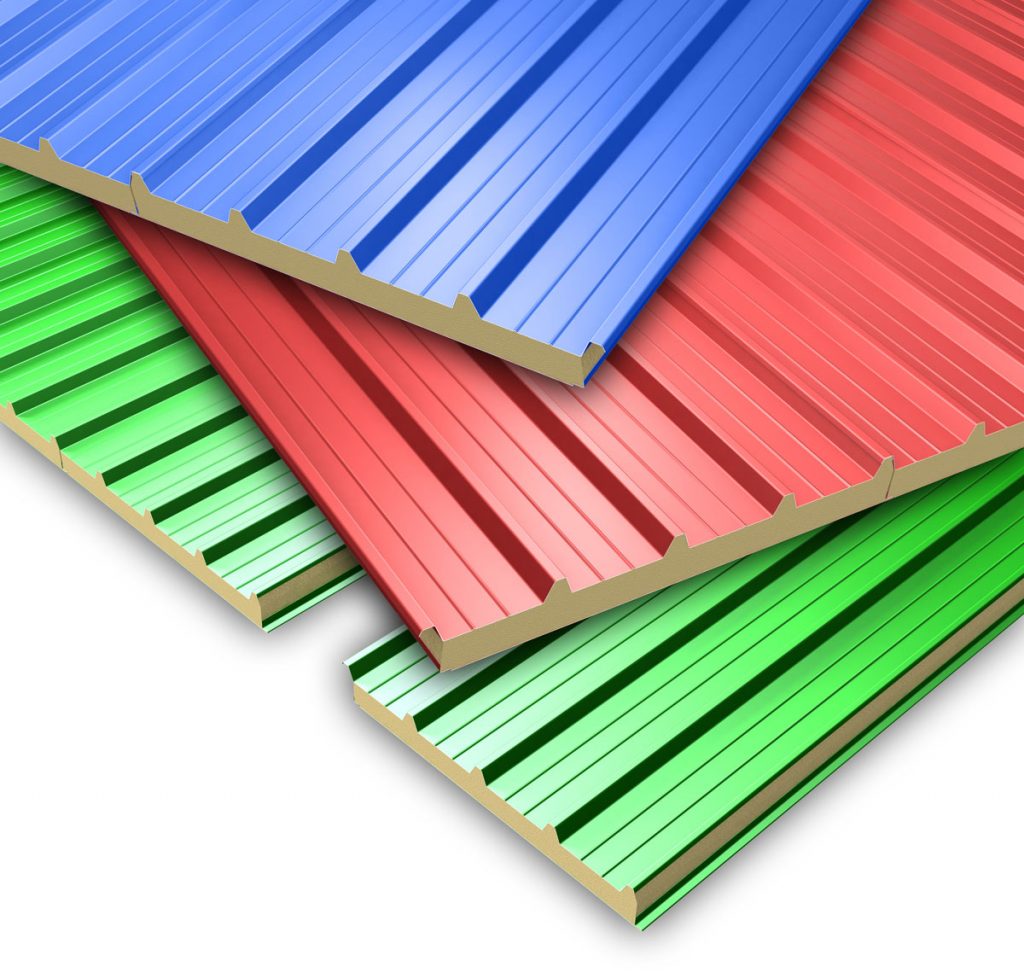

According to the type of thermal insulation, the core is: mineral wool; glass-fiber; polyurethane foam; polyisocyanurate foam; expanded polystyrene; there are panels from other materials.

According to the type of coating, several types of panels are distinguished: metal-coated; plasterboard, plywood, wood or chipboard (cement-bonded particle board) coated; PVC-coated; paper-coated.

According to the type of polymer coating, several main types of coatings are distinguished: polyester (marked with PE) - suitable for all climatic zones; plastisol - applicable for both internal and external structures; polydifluorionate (PVF2) - resistant to mechanical damage; polyurethane - resistant to temperature changes, corrosive and aggressive substances, ultraviolet radiation.

Wall panels are made of various insulating materials protected by rigid sheet materials. For this, PVC, polyurethane foam, mineral wool, PPS (expanded polystyrene) are used. Regardless of the type, the products are suitable for inexpensive and fast construction. The sandwich panel consists of 3 layers. The upper and lower ones are protective, most often they take galvanized steel for this. Resistant to corrosion, temperature changes and reliable. The thermal insulation material is located between the protective layers. The main requirement for it is a low coefficient of thermal conductivity, moisture resistance and strength.

Sandwich panels" UPS " are produced according to modern standards and are distinguished by high quality, thermal insulation and strength. With this product, you will reduce operating costs and construction time.

Blog

Subscribe to our newsletter