Sandwich panel factory

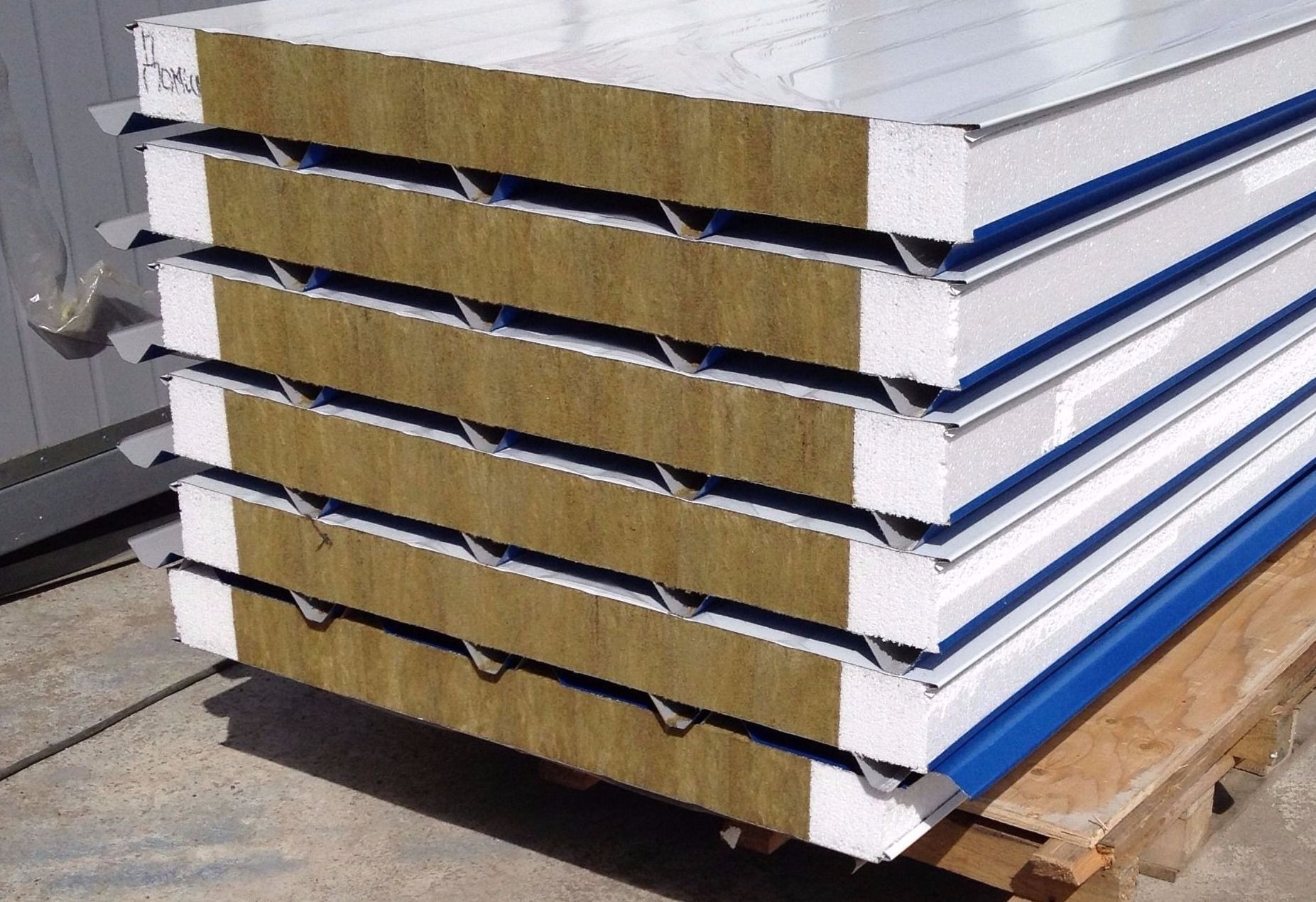

Sandwich panels have gained particular fame for being an affordable building material over the past 50 years. Combined materials there are basically two processes for the production of this material, always consisting of Two Face layers (hard metal or elastic layer such as thin aluminum, paper or membranes, depending on the area of application) and the main insulating filling:

Continuous process

All used materials are processed together and the panel formed by finishing is cut to a maximum length of 15 m without stopping the line.

This line is carried out in the manufacture of panels of medium thickness (40-50 mm) with metal upper layers at an average speed of about 14 meters per minute.

The materials are processed separately, that is, the face sheets are shaped and cut to the desired (width standard 1m, length from 1m to 15m) length. The foam is then combined in a pumped press.

In addition, this process has a lower productivity, incomparable with the continuous process.

Sandwich panels, which are used for roof and facade cladding of buildings, interior partitions with insulation or the creation of cold depots, have a fairly wide scope of destination.

Its light weight, easy application and strong insulating ability have made this product one of the most used materials in the construction site.

UPS Construction sandwich panels, which are manufactured using high technology by selecting quality materials, are suitable for any type of Use and are distinguished by their durability for many years.

Blog

Subscribe to our newsletter