Production of sandwich panels

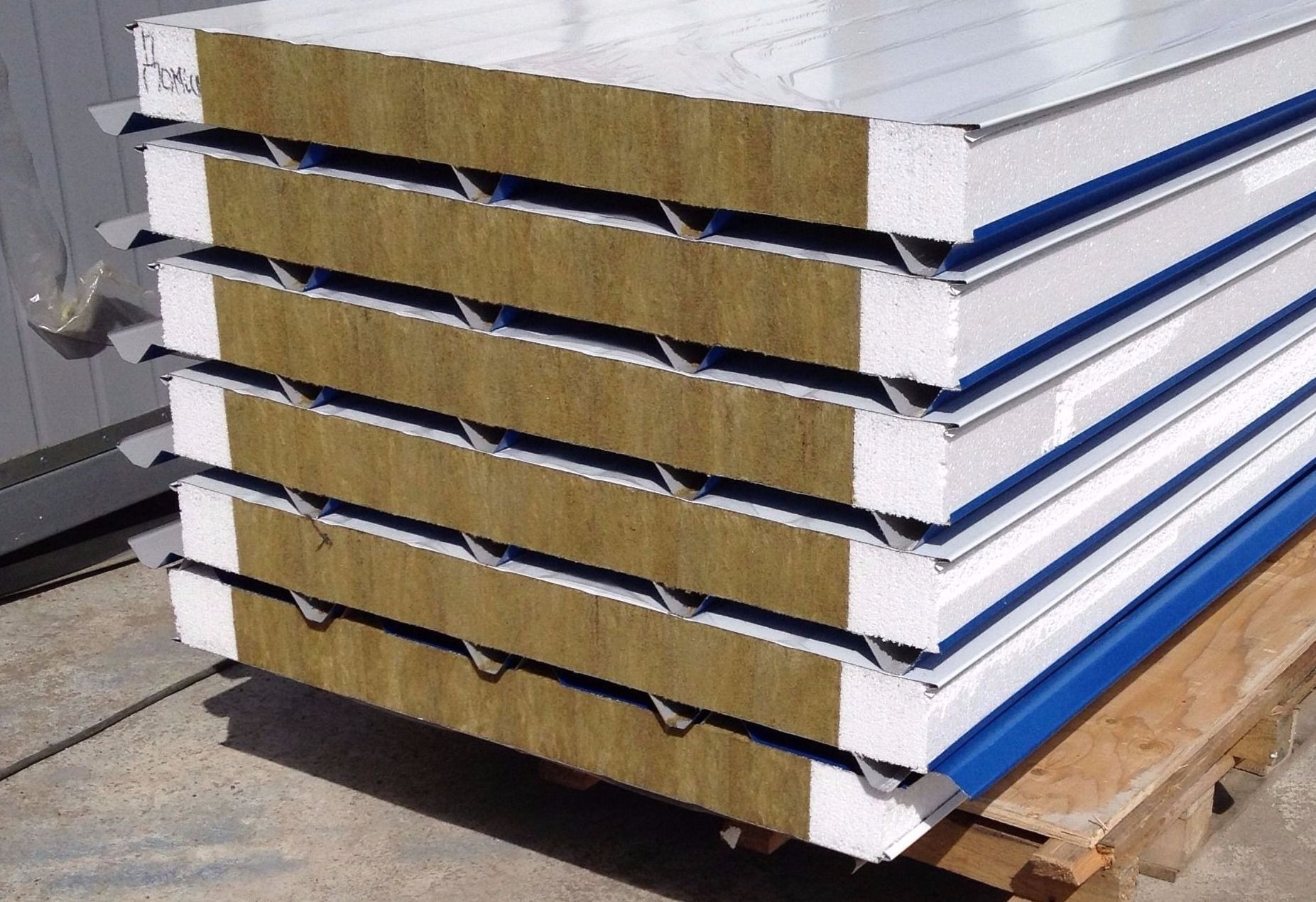

Although the structure of individually manufactured sandwich panels and their application differ significantly according to the adopted production technology, their main elements are often considered as follows:

- Outer cover made of profile steel;

- Internal structural core, which also functions as a thermal and acoustic insulator.

Sandwich panel production, painted galvanized sheet, aluminum or stainless rolls; produced by forming polyurethane, stone wool, Pir, glass wool, XPS or EPS polystyrene material by pressing or filling in the sandwich panel machine. After the polyurethane Pur sprays are sprayed onto the sandwich panel (38-40 DNS), the desired lengths are cut with the sandwich panel machine. The sandwich panel is lifted onto the roof by the sandwich panel manufacturer after its roof is formed, which can be taken to vehicles by elevators, thus completing the sandwich panel production.

There are varieties that, due to their structure, provide water, sound insulation and fire resistance of these panels. The insulating layers used in the manufacture of sandwich panels provide thermal insulation in various indicators. They are long-lived, do not harm the environment, do not form bacteria or keep them in themselves. Because they are lightweight, they are convenient in carrying process and cost. It is the most ideal building material that can be applied in all structures with steel, wood or reinforced concrete structures.

Blog

Subscribe to our newsletter