Why choose sandwich panels?

Over the past few decades, sandwich panels have become a revolutionary solution in the construction sector.

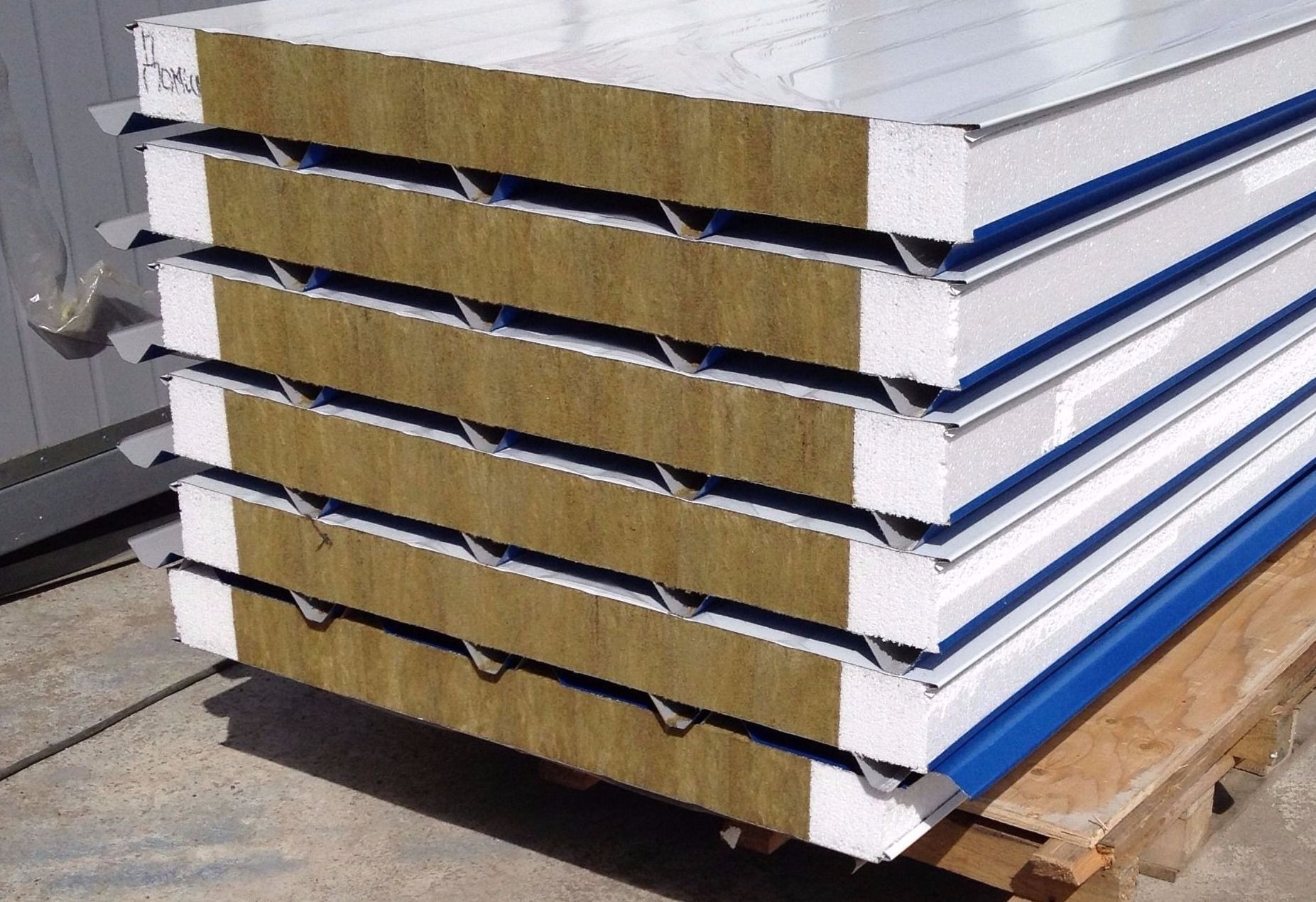

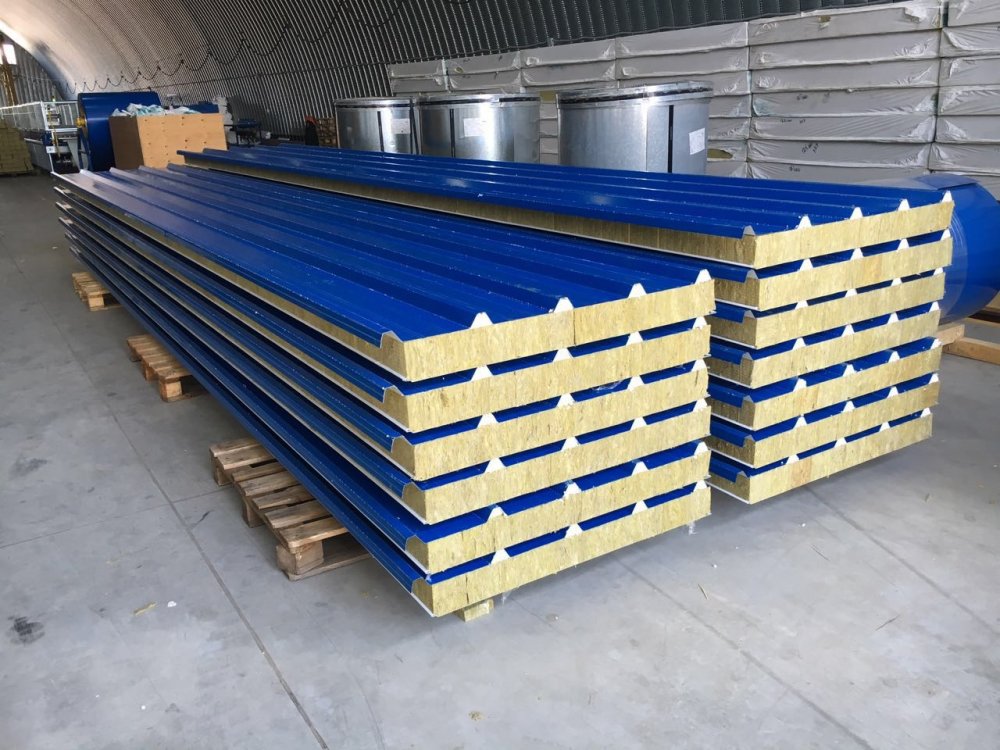

Due to its purpose, this material performs two functions – partition (for roofs and walls) and thermoisolation.

In the construction market there are sandwich panels of different length (from 3 to 15 meters), thickness (from 50 to 120 mm), different filler (foam polystyrene, stone, polyurethane), different surface (microprofiled, smooth or hollow), different protective surface and different RAL code.

Sandwich panels have a number of advantages over other structures. During the use of sandwich panel, first of all, the upgrade time of the structure is shortened, and the process is Cheaper. These panels, which are a ready-made component, are ready and suitable for assembly at any time.

Sandwich panels are available in three basic versions. Panels with Polyurethane Filling are suitable for thermal insulation. Panels with masonry are suitable for sound and flame insulation. Sometimes, these two types of insulation panels are used in the same construction.

Apart from all the additional industrial advantages, construction companies are gradually beginning to pay special attention to the aesthetic appearance of the panels. Interest in the building usually depends on its appearance. Therefore, the individual features given to the building recently are of great importance.

Objects made of sandwich panels can be freely designed. Since the material is easy to process, the construction of shops, warehouses or workshops, car dealerships, gyms, logistics centers in European countries is increasingly being carried out from sandwich panels.

Blog

Subscribe to our newsletter