Special installation nuances of sandwich panels

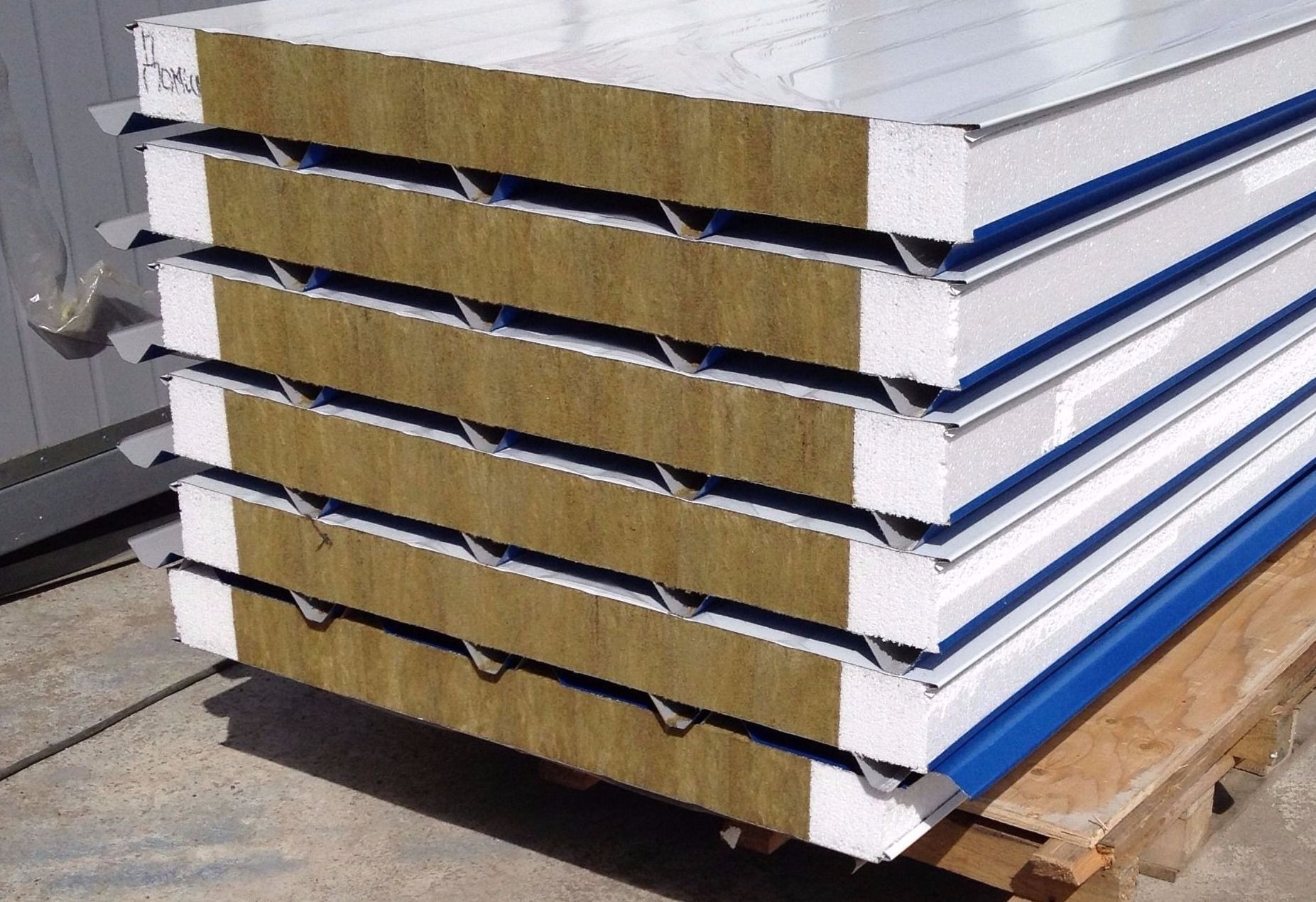

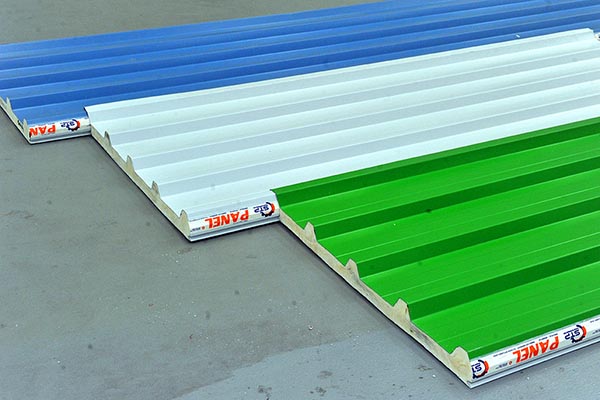

Before giving information about building a sandwich panel, it is necessary to explain what a sandwich panel is. Roof, facade, etc., providing resistance to impacts such as fire and gravity to ensure heat, sound, waterproofing. it is a covering material used in places. It consists of three layers. These are the insulation layer, inner and outer faces. Easy assembly and aesthetic structure are some of the characteristics of this material. In addition to all this, a variety of accessory options also make this material an indispensable choice of the construction site.

As for the application process of sandwich panels, the point that must be taken into account above all is that the panel is installed in the opposite direction to the prevailing wind. It is wrong to always use the same number for the number of screws to be used in the assembly. This situation varies due to various factors, such as the strength of the wind. The size for overlapping in Panel length should be at least 15 cm. The sealant tape must be connected between the overlapping metals with the help of pop rivets or pull screws. The points in contact with the wind must be attached to the purlins.

Another golden rule to consider when assembling sandwich panels is to prevent materials such as steel purlin, concrete, plaster from joining with the panel metal coating. The substances used for this purpose are paint or suitable insulation products. As a precautionary measure against oxidation, aluminum products should be protected from the factory to the setting process. The most important factors to consider are water, snow and humidity.

Blog

Subscribe to our newsletter