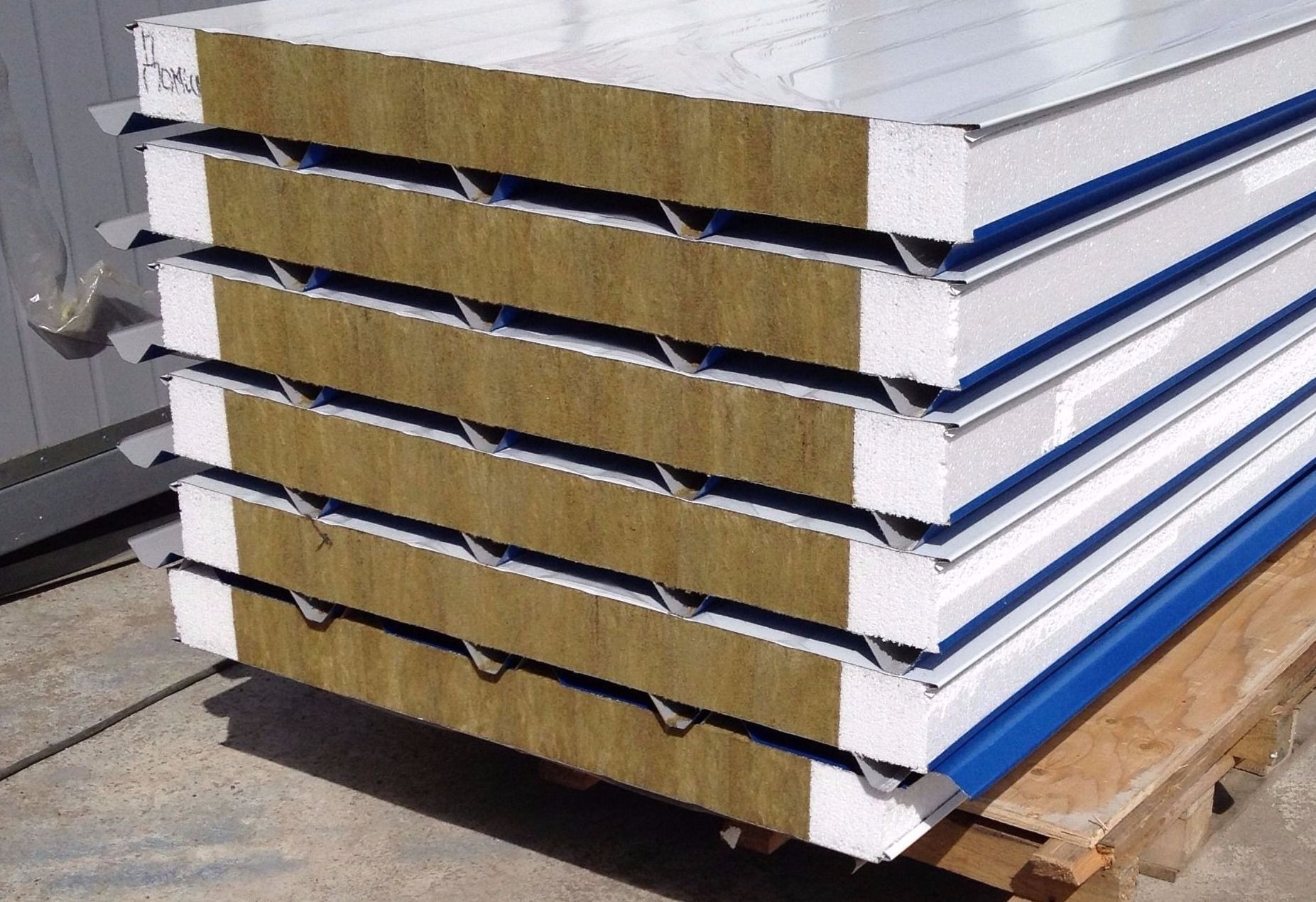

Load-bearing capacity of sandwich panels

Sandwich panels are a composite material consisting of a polyurethane or dashyun filling between two metals.

It is widely applied in many solutions such as roofs, facades, partitions, cold depots and the like. Quick and easy assembly, high insulation make this product even more prominent.

Mechanical strength, which is one of the most important features, has been repeatedly tested and justified in accordance with high standards. Modern studies have established that the width and thickness of the filling material play a huge role in the load-bearing capacity of the sandwich panel. Despite its light weight, it has a high load-bearing potential. We can do this more clearly in sandwich panels intended for the roof. When quality raw materials are used, high-quality and durable panels are produced.

Studies for measuring the load-bearing capacity of sandwich panels have been applied in the period from minutes to months when the weight of the load can be increased relatively.

Due to the distance between the Purlin, the distributed load carried by the panels at a distance of about 7 meters averages 35 kg/m2, and at a distance of up to 1 meter-1500 kg/m2. The tests were carried out on panels weighing 15 kg/m2. In the calculation of Panel weight, the density of polyurethane (PUR) is taken 40 kg/m3, the density of polyisocyanurate (PIR) is taken 42 kg/m3.

However, an excessive increase in the thickness of the filler can negatively affect the productivity of the panel

Blog

Subscribe to our newsletter