Information about our work

Established in 2015, Universal Procurement Service is one of the leading companies in the country, operating in construction, energy, oil and gas, agriculture and other important sectors.

The work we do and the services we provide are only a visible part of our activities. The main part of the production, which remains "behind the staff", often remains unnoticed.

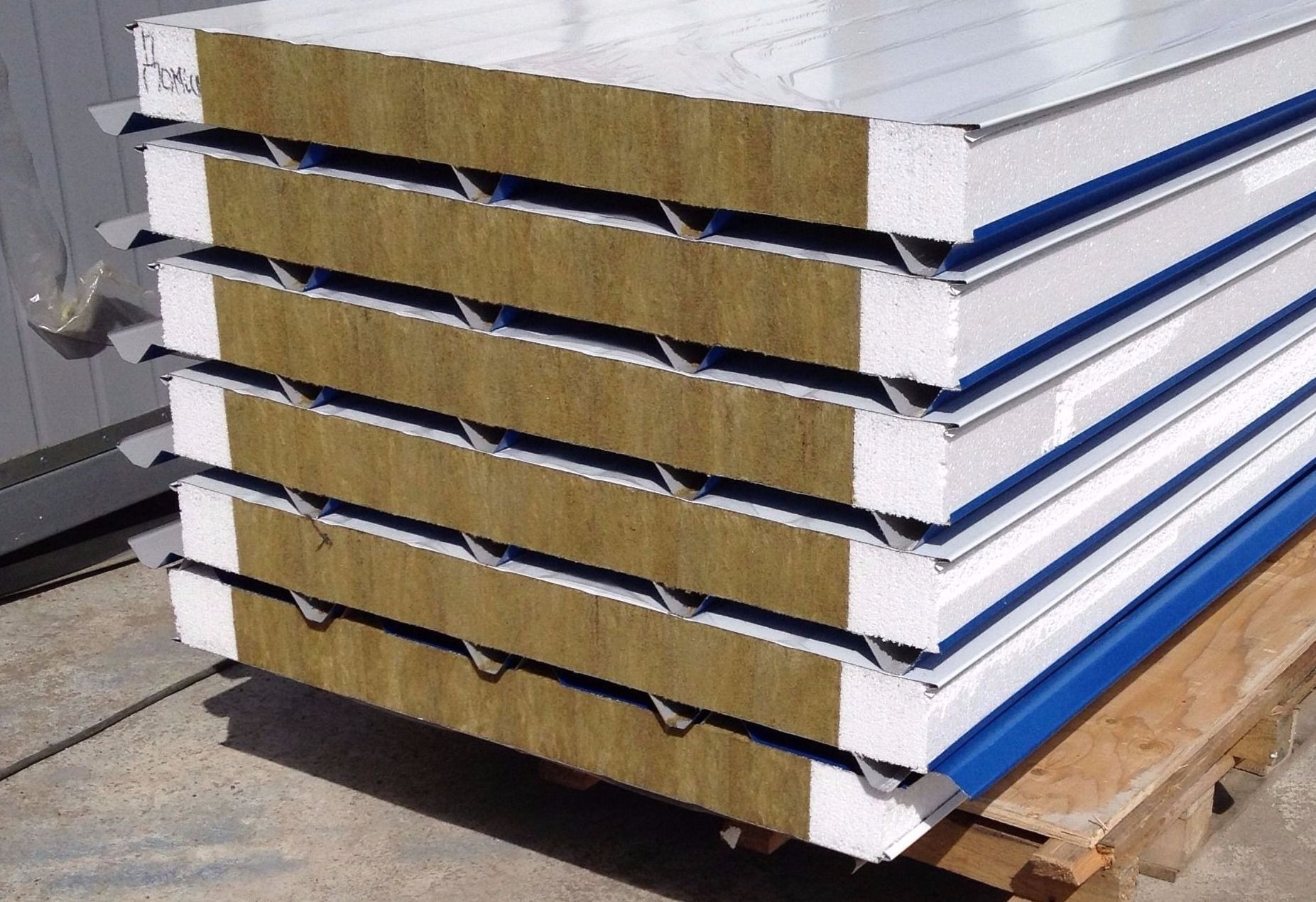

In this post, we decided to tell you about the work process going on in our workshop. It is not only necessary to purchase equipment, machine tools and tools for the high-quality operation of our production and the proper implementation of production technology. The main part of the production process is teamwork. So, our shop employs professionals of various profiles, wide and narrow specializations. Among them are blacksmiths, welders, painters, Turner, flooring Masters.

Our team, which is currently working mainly on the development of modular containers, is developing this work with high professionalism and in a short time. In our workshop, cutting, assembly and assembly of the carcass parts of containers are carried out. In the next stage, materials are cut according to the dimensions of the containers, for example, sandwich panel, profinastil, foam plastic. Power supply lines are laid. After the painters of our workshop have done the color work, doors and windows are installed in modular containers. Laminate flooring applied by our flooring professionals in our workshop completes the construction process. After that, our block-containers are sent to the destination point, installed on the spot.

Blog

Subscribe to our newsletter