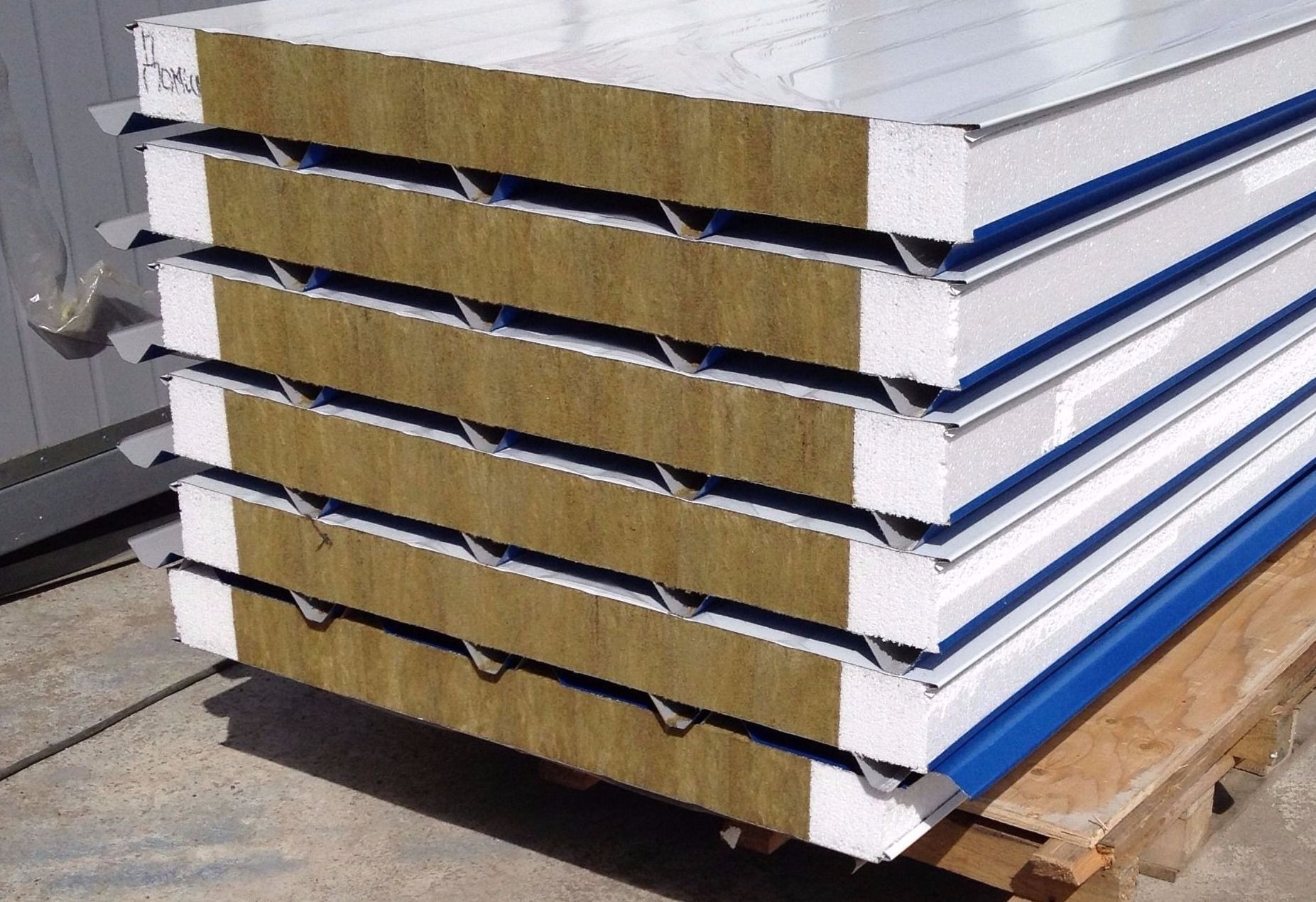

About roofing sandwich panels

Today, new technologies are increasingly beginning to take the place of traditional roofing materials.

Quite strong, heat-retaining roofing materials are made from these materials, which are essentially different from the old ones. The roofing materials produced by Uniprocurement company from sandwich panels are based on a relatively new, but already proven technology in the construction sector.

The use of sandwich panels in construction provides an opportunity to solve numerous architectural issues. Due to the use of non-combustible materials in the production process, the product has fire-resistant properties. The maximum utilization rate of sandwich panels for roofing materials manufactured by Uniprocurement is 70-80°C, and the maximum temperature resistance is 100-110 °C.

Modern roofing sandwich panels are produced in the form of a three-layer structure: heating material is used in the middle layer, and metal plates are used as double-sided coating material. The size of these metal loveheads is 0.3 – 0.5 thick.

The possibilities of using roofs assembled from sandwich panels are quite wide. It is because of him that the use of the material in construction is gradually increasing. Sandwich panel roofing is actively used in the construction of warehouse and commercial enterprises, residential complexes and special facilities. At the same time, roof tiles made of sandwich panels look fashionable and are also more functional.

Sandwich panels from Uniprocurement are distinguished by such characteristics as high quality, thermal insulation, easy installation and disassembly, longevity, high resistance to fire and water, sound insulation, corrosion resistance.

Blog

Subscribe to our newsletter